PARIS, France, Jan 17, 2025 – FOSECO and ESI Group announce a new cooperation.

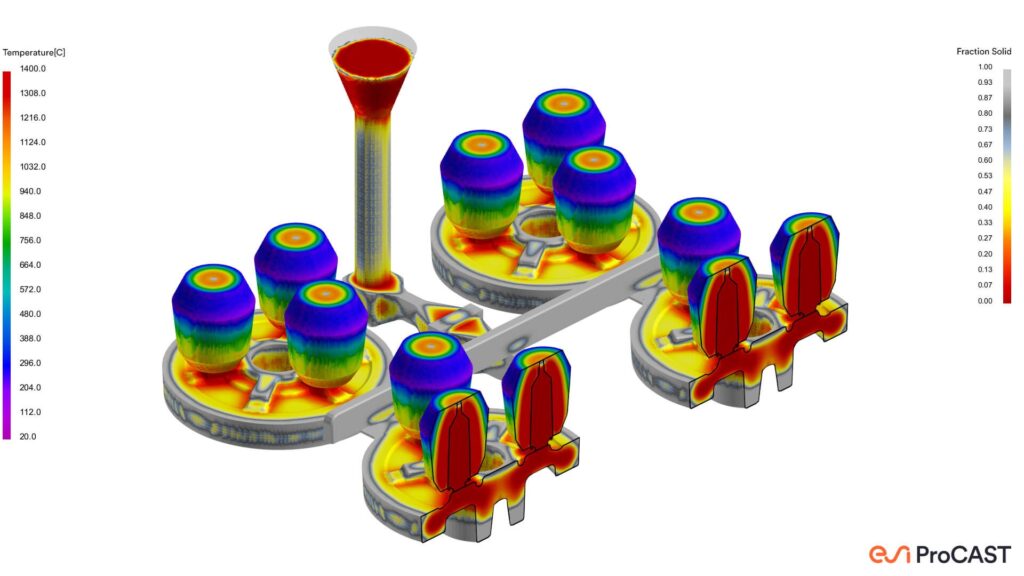

Thermo-physical data for the FOSECO feeder sleeve and filtration product ranges are integrated and made available in ESI’s ProCAST (& QuikCAST) software. ProCAST provides insights into the dynamics of the casting process, empowering foundries to evaluate, validate, and optimize their casting processes, thereby reducing manufacturing costs.

The integration of Foseco’s feeder sleeve and filter thermo-physical data into ProCAST enables customers of Foseco and ESI ProCAST to execute simulation projects effectively.. By assigning the product-specific material properties to each feeder and filter, simulated filling & solidification results become more reliable.

The improved accuracy and confidence lead to faster decision making, optimizing gating and feeding system design with fewer simulation iterations for better casting quality and yield.

KEY BENEFITS:

- Accurate Simulations: Foseco and ESI‘s collaboration integrates Foseco’s sleeve & filter data into ProCAST for precise casting process & defect predictions, better decision-making, reducing iterations and enhancing quality with maximized yield.

- Efficient Workflow: Having Foseco‘s data accessible in ProCAST helps foundries eliminate uncertainty in simulations, and boosts productivity.

- Worldwide Impact: Initially, Foseco datasets for products relevant to Ferrous Foundries in Europe will be available, paving the way for regional and global expansion.

Initially focusing on products relevant to Ferrous Foundries in Europe, this integration sets the stage for future expansions, with plans to expand geographically in phases. . Foseco and ESI Group are committed to providing foundries innovative solutions to improve efficiency and drive innovation in the casting industry.

Source: ESI Group