CHARLOTTE, NC, Jan 29, 2025 – SPX FLOW has collaborated with Siemens to highlight cutting-edge digital twin technology at the MxD (Manufacturing x Digital) center in Chicago. A premier hub for innovation in manufacturing, MxD is driving advances across industries such as food and beverage, chemicals, and batteries.

At MxD, SPX FLOW and Siemens are demonstrating the transformative potential of digital twin technology. The technology is enhanced by industrial 5G connectivity and modular production using software-defined module type package (MTP) concepts, showcased through an automated mixing tank with an associated digital twin.

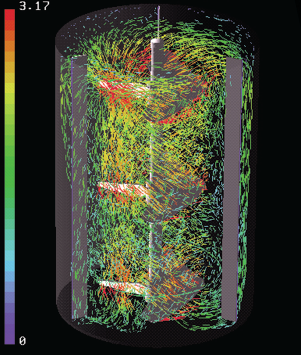

The collaboration combines SPX FLOW’s fluid processing solutions (including mixers, pumps and valves) and expertise with Siemens’ IoT connectivity solutions and computational fluid dynamics (CFD)simulation capabilities to create a digital twin (a precise virtual replica of the physical systems) of an autonomous mixing tank concept. This enables users to design, test, and optimize fluid systems virtually, mitigate risks, improve efficiency and accelerate innovation.

SPX FLOW supports Siemens in showcasing how virtual simulation can transform production. By creating a digital twin of a flexible, autonomous process, manufacturers can improve production, verify throughput, and adapt easily than with traditional fixed production lines. This method also enables continuous mixing of materials or ingredients while an autonomous mobile robot (AMR) navigates the plant, ensuring maximum production capacity and consistent quality.

“Our innovative fluid technologies combined with simulation-based digital twins and AI-driven modeling enables us to deliver faster, customer-focused solutions,” said Tyrone Jeffers, SPX FLOW vice president of global manufacturing and supply chain. “Together with Siemens, we are prioritizing flexibility, efficiency, and sustainability, paving the way for a new era of manufacturing excellence.”

CFD modeling and IoT conditional monitoring support SPX FLOW’s product development by:

- Accelerating Innovation: Reducing modeling time while improving precision.

- Improving Efficiency: Refining designs with enhanced flow analysis.

- Integrating Seamlessly: Aligning digital twins with real-world applications.

- Smart Products: Leveraging IoT conditional monitoring to optimize equipment performance and enable predictive maintenance.

“This collaboration is a win for us and a huge win for our industrial customers,” said Del Costy, managing director, Americas, Siemens Digital Industries Software. “Working together with SPX FLOW and harnessing the power of live connections between the physical and digital worlds in digital twin models, we are helping customers to achieve faster time to market, optimize system performance, reduce costs and resource usage, and deliver tailored, application-specific solutions to meet their unique needs.”

About SPX FLOW, Inc.

SPX FLOW, Inc., headquartered in Charlotte, NC, is a leading provider of process solutions for nutrition, health, and industrial markets. The company was established in 2015. It specializes in engineering, designing, and manufacturing a wide range of products, including pumps, valves, mixers, filters, air dryers, homogenizers, hydraulic tools, separators, and heat exchangers. These solutions serve industries such as food and beverage, power and energy, chemical processing, compressed air, mining, and other industrial sectors. Operating in more than 25 countries with a workforce of approximately 3,900 employees, SPX FLOW has a global presence and serves customers in over 140 countries. The company is recognized for its innovative and sustainable solutions that improve the world through advanced process technologies.

About Siemens Digital Industries Software

Siemens Digital Industries Software provides comprehensive solutions for digital transformation, offering software and services that enable companies to improve product design, manufacturing, and operational processes. It serves a wide range of industries including automotive, aerospace, industrial machinery, electronics, and consumer products. Siemens Digital Industries Software has contributed towards innovation in manufacturing and product lifecycle management (PLM). The company is headquartered in Plano, TX, and is part of Siemens AG.

Source: SPX FLOW