If you were to design the perfect electric car from scratch, you would have a motor in each wheel. An in-wheel motor, or IVM, saves mass (as much as 250 kg, according to SAE) by having no drive line, increasing the range (as much as 36%, according to Elaphe, an IVM manufacturer) and can get you in and out of tight spots (each wheel can rotate as much as 90 ° about the vertical axis). Embraced by a bicycle industry jolted into life, EVMs got little love from automotive designers. But recently, there has been a spark of hope. The leading IVM maker, Protean Electric, got the bulk of a $15 million award from the UK government – and priceless international attention— to further in-wheel power electronics.

Electrical vehicle design borrows much from conventionally powered vehicles: the motor under the hood connects to the wheels. The size of internal combustion engines and the attendant systems needed (fuel, cooling, lubrication, aspiration and exhaust) enforced its placement. The electric motor has no such constraints. They are far more compact. You can place them anywhere. Why not put them right in the wheels? You could do away with crankshafts, drive shafts and differentials needed to transmit power.

A Little History

IVMs, or hub motors, are not an original idea. Credit for invention of hub motors is spread among several inventors. One version was invented by Hosea W. Libbey in 1897. They were used in the earliest cars, such as the 1900 Lohner-Porsch shown above. They disappeared as the internal combustion engine gained popularity.

The IC engine became the mainstay, and it was only when battery technology’s specific power became significant compared to gasoline that its dominance was threatened.

Reinventing the Wheel

But even as an electric motor replaces the IC engine, its place in the vehicle’s center remains. Why? The auto industry offers several excuses. IVM-equipped wheels can’t handle high speeds. They are too expensive. They result in too much unsprung mass – the mass of a vehicle that is not isolated, not protected from the road’s hard knocks by springs – certainly a valid excuse in the late 19th century when roads were best traversed by horses.

In the race to get new electric car designs on the road, the easiest and fastest method would be to put the motors under the hood and leave the drive line components in place. You could make a frunk from the unused space. Why reinvent the wheel? Electric car companies distributed the motors (Tesla to center front and rear, Rivian one for each wheel), but none dared go all the way with motors in the wheels. Mercedes made a prototype of its vaunted SLS model with four near-wheel motors but it never got into production.

What do Mercedes engineers know? Protean engineers have taken over the IVM challenge, flaunting IVMs on a Mercedes E-Series sedan. With over 350 patents, Protean may claim it is reinventing the wheel. Their story, as displayed on their website:

- IVMs Have Space Efficiency: By eliminating traditional driveline components like the gearbox, differential, and driveshafts, in-wheel motors free up significant space within the vehicle. This leads to more flexibility in vehicle cabin design, allowing manufacturers to optimize interior layouts for passenger comfort or increase space for batteries and cargo. [Or the extra room could be used for more batteries.]

- Improved Maneuverability. Each wheel in an IWM can be individually controlled allowing for enhanced handling through torque vectoring. [IVMS almost 90 degrees, letting IVM-equipped vehicle enter a parking space sideways].

- Better Performance. Torque is applied directly, leading to better stability, better response time, better cornering, and improved driving dynamics.

- Greater Energy Efficiency: In-wheel motors are more efficient than traditional drivetrain systems because they eliminate power losses in differentials and driveshafts. Losing the drive line components also sheds mass [as much as 500 lbs, according to SAE], leading to longer driving ranges and reduced charging frequency.

- Enhanced Modularity and Production Efficiency: IWMs simplify the vehicle assembly process by reducing the number of required components with IVM essentially a plug-in module, including steering and brakes, reducing development time and cost.

- Better Driving Experience: Besides offering superior handling, IWMs improve the overall driving experience by providing smoother acceleration, better road feedback, and more precise control. These benefits are achieved without noticeable drawbacks in ride quality due to unsprung mass, as the impact on comfort is minimal for most drivers. [With this claim, Protean answers what may be biggest criticism: more unsprung weight].

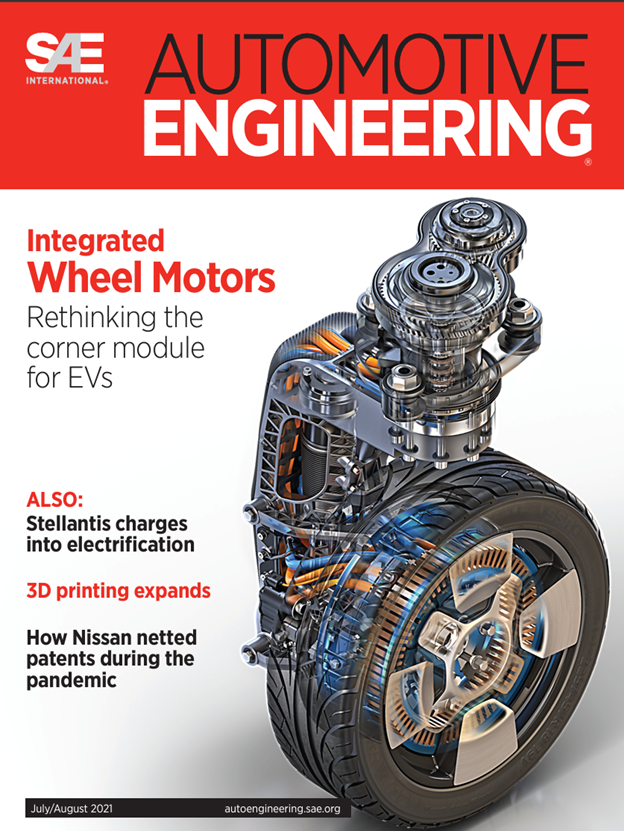

The automotive industry started to turn the page – literally — to IVMs in the 2021 issue of SAE (Society of Automotive Engineers) put IVM on the cover and concluded with “the future looks promising for IWMs to revolutionize vehicle, design development, manufacturing and servicing.”

Local Motors for Local Motors

Yet, no EVs are rolling off the assembly line on IVMs. The company’s biggest near success was Local Motors, which designed IVMS into Olli, a boxy, autonomous electric vehicle. Local Motors was a perfect platform for IVMs as IVMs are literally local motors and their vehicles, one of which was 3D printed, became a media darling. Olli went into limited production and got some use as a shuttle but remained a novelty. Local Motors ran out of money and went out of business in 2022.

A similar fate befell EV startup Lordstown Motor Corporation, which implemented in-wheel motors from Protean competitors, Elaphe, on their Lordstown Explorer pickup truck. However, the company went bankrupt after changing its name to Nu Ride in 2023.

Companies Developing IVMs

Protean Electric faces competition from several companies in the sole business of developing and producing in-wheel motor technology.

Protean Electric and Elaphe are front runners among companies that focus specifically on designing and developing in-wheel motors.

- Protean Electric (Surrey, England) has been funded to the tune of $194 million and has 95 employees.

- Elaphe, based in Ljubljana, Slovenia, has $4.9 in funding and between 100-250 employees.

- GEM Motors, also based in Ljubljana, Slovenia, has yet to disclose funding and is estimated to have 25-100 employees.

- e-Traction, based in Apeldoorn, Netherlands, also does not disclose funding and is estimated to have 25 to 100 employees.

- 5. Ziehl-Abegg, in Kuenzelsau, Germany has 2,400 employees but a group devoted to IVMs.