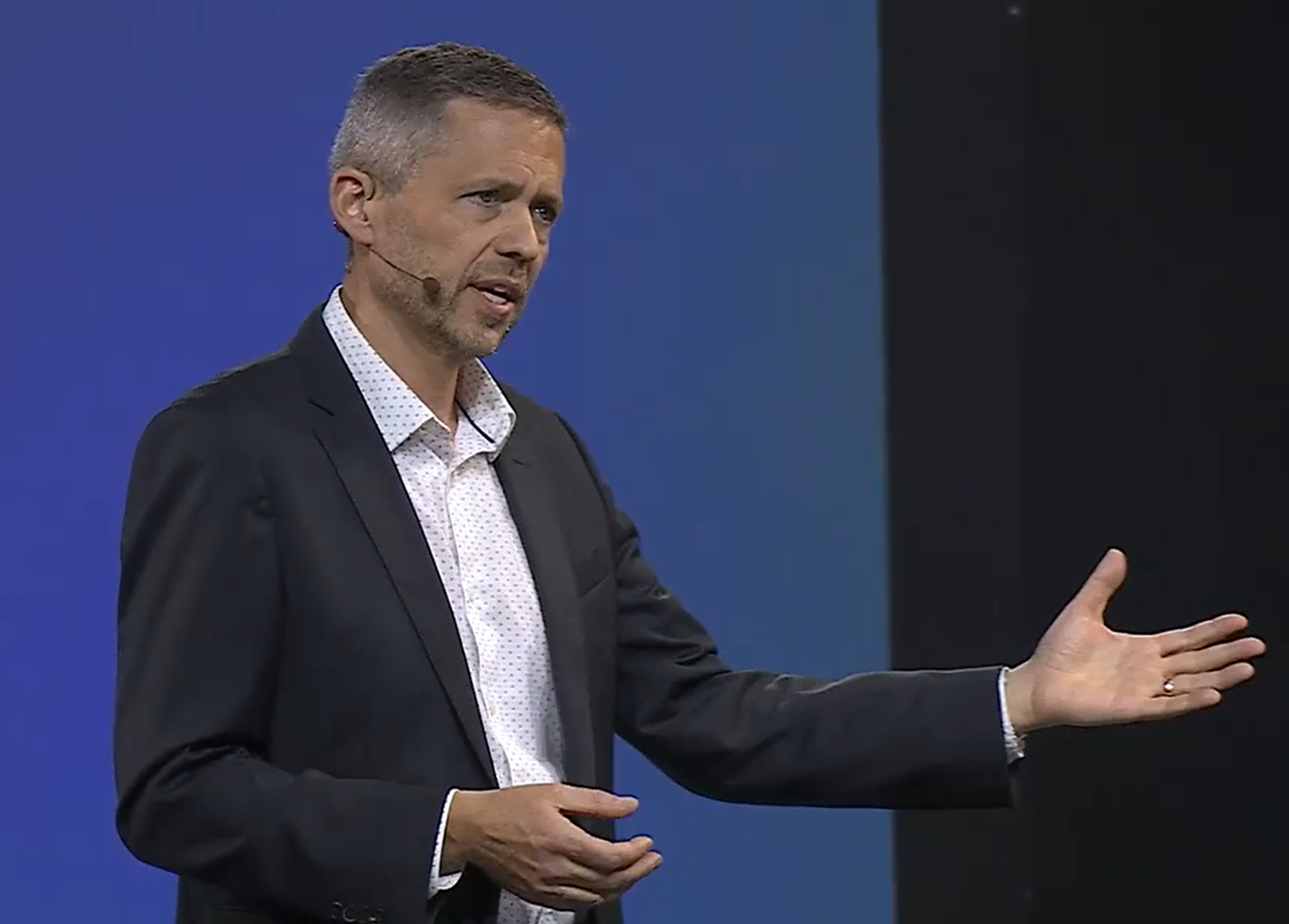

Stephen Hooper is conducting a masterclass in presenting at AU2024. I’ve come to expect that from him over the years. His elocution is absolute and his timing is perfect. He manages to synchronize with the video that is playing! I don’t know how he does it. His accent doesn’t hurt. He’s British.

He is making Fusion quite compelling, but it is oratory and stage presence that steals the show. I wonder if he studied acting. He certainly plays his part well in his division’s (Design and Manufacturing) flagship product, Fusion.

I want to buy Fusion after listening to Hooper as if, instead of AU, this was the Shopping Channel selling Ginsu knives.

Shots Fired

For the AU2024 drinking game, “AI” took an early lead, but “data” has overtaken it.

Fusion is getting all the love from Autodesk, a gifted child with multiple talents, compared to Inventor, the stodgy spinster who lives at home. All of Autodesk’s attention is going elsewhere, towards Fusion. And Autodesk keeps heaping features on it. Like AI Assistants.

Fusion already does dimensions and makes views automatically. In just a few months, it will be able to preserve symmetry, even in big assemblies. For example, if the track assembly on one side of a gigantic earthmover is changed, the other side changes automatically.

Hooper gives an example of how FlexSim, Autodesk’s factory design application, could have helped with the placement of a new CNC machine in Autodesk’s Birmingham manufacturing location not just getting in the door but also maximizing workflow.

Leading Off

First on stage for Autodesk’s manufacturing division, Srinath Jonnalagadda, VP of Industry Strategy for Design and Manufacturing; what is foremost on his mind? You guessed it. Data.

Data, in this situation, is what is left when you break down big files into their constituent parts. Turning files into data is a high priority at Autodesk. That shouldn’t worry the users of file-based programs whatsoever, we are told. Every AutoCAD, Revit and Inventor will be able to operate as they always have. But behind the scenes, files will have been atomized into databases.

Apparently, storing information as data instead of files allows collaboration via the cloud and interoperability. It is ironic that Autodesk, once keeping DWG files under lock and key, firing resellers if they sold competitive software (notably SolidWorks), is now lauding interoperability and brotherliness sharing files.

“It doesn’t matter what tools a company uses, ours or someone else’s,” says Jonnalagadda.

Jonnalagadda calls to the stage Andrew Warren, senior manager at Bridgestone, Dr. Carlonda Reilly, VP and CTO of Kennametal, and Voho Sea, senior designer at Kia.

From Voho, we hear how AI should be treated like a new employee who has to be trained.

“You can’t expect AI to get it right away.”

Kia is probably using Autodesk’s Form Explorer, the rechristened BlankAI, which creates car exteriors by the thousands.

The discussion turns towards the skills gap, either a result of an aging workforce, manufacturing going overseas, a shortage of youngsters entering, or all of the above. AI is seen as a force multiplier at Kennametal.

Since ChatGPT is remarkably good at generating code, having digested the entire contents of GitHub, generating machine code is mere child’s play.

Autodesk claims natural language prompts in plain English (like write the code to rough out this box”) save 95% of a CNC programmer’s time. Unlike every other boast made by CAD, CAM, and CAE vendors about time savings, this one sounds reasonable.

Warren was hired many years ago at Bridgestone to install the Autodesk vault. He never left.

Bridgestone manufacturing machines are huge and expensive, and their worth is far in excess of the buildings they are in.

“The building keeps our machines dry,” he says.

Hear that, AEC guys?“ Jonnalagadda says to the audience. No penalty flag is thrown. The AEC keynote was earlier and all the AEC guys have left the building.