FRAMECAD, a maker of steel-forming machines and software for the manufacture and implementation of cold-formed steel (CFS) structural members, has introduced Nexa, a “production management platform” for building projects made using CFS.

Nexa is meant for any company that builds with CFS, from panelizers (those that make panels, such as walls, floor, or roof panels for modules) to builders that build whole pre-fab modules.

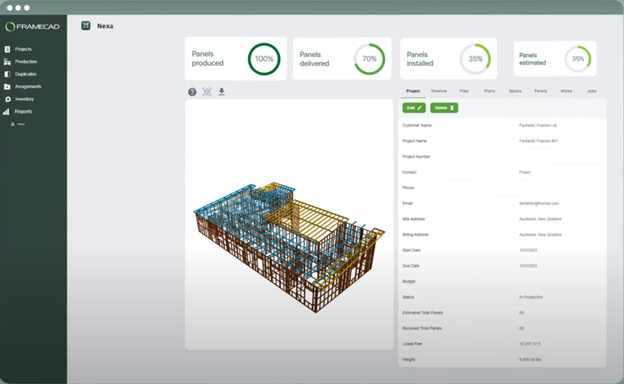

Nexa will import a CAD or BIM model and take over from there, controlling how the CFS members are formed out of stock, a roll of steel, how they are assembled, showing each member in all its detail, and following through to its assembly on site. Throughout it all, a dashboard view tracks the project, showing progress, including percent completed.

Why Use Structural Parts Made From Sheet Metal?

Sheet metal may seem an unlikely choice for buildings. They are accustomed to thick, heavy structural members. Still, with the correct shape and sufficient support to prevent buckling, they can be highly efficient structurally, with strength-to-weight ratios better than wood and conventional structural steel, AKA hot-rolled steel, such as I-beams. Such structural efficiency, as well as lower cost, make them the first choice in certain types of construction, particularly modular construction, but increasingly in low-rise and mid-rise buildings. It also helps that they can be cut faster than hot rolled steel and more precisely than wood. Their light weight makes them easy to move around during manure and construction, as opposed to weighty I-beams and timber beams that require cranes to lift and position.

Provide real-time data for capacity planning and inventory management. Nexa can track materials and ensure compliance with regulations while maintaining traceability for both materials and processes.

Project Management: Nexa users get real-time visual updates on project project progress. Centralized data access, AKA a single source of truth, enables all stakeholders, from factory teams to field workers, to collaborate more effectively and speed up workflows. Real-time dashboards show easy-to-read gauges for how much of a building has been built.

Nexa also helps with logistics and optimizes stacking, packing, and delivery coordination.

What is Cold-Formed Steel?

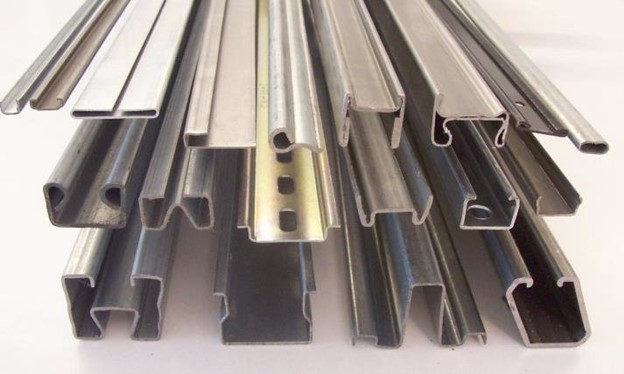

Cold-formed steel framing (CFS) refers to a construction technique where thin sheets of steel, shaped by rolling or pressing at room temperature, are used to create structural elements within walls, floors, roofs, etc.

Forming sheet metal into structural shapes has the apparent advantage of being lighter than both solid wood members or hot-rolled steel – but must be designed to overcome the sheet metal’s tendency to buckle under compressive loads, much less likely in thick, heavy shapes. This requires additional design considerations and often more bracing or stiffening.

Compared to wood, CFS can be seen as preserving trees and natural resources. And it doesn’t rot or is prone to pests like termites. It can be cut more precisely and hold its shape, while wood has “movement” and will warp, shrink, and expand. Being non-isotropic, it is never the same way in all directions. Steel is much better behaved. It’s no wonder engineers prefer steel over most other materials.

So Why Are We Still Using Wood?

With all of wood’s disadvantages, why use it all the time for residential construction? Oh, yeah. It is, or was, plentiful. This convenience of plenty built entire cities of wood, like San Francisco made from California redwoods. The city burnt to the ground in the 1906 earthquake as the wooden building with wooden roofs was only too quick to ignite.

However, in commercial building design and construction, architects and engineers need to be aware that by its nature, CFS weakens more quickly than hot-rolled steel in fires. Its thinness makes it harder to weld and gives corrosion a better shot at weakening the whole member. You must also compensate for its thermal conductivity, which is practically a thermal short circuit, while wood is an effective insulator. Also, if you think your next motel walls are thin, it’s more likely the fault of CFS, which transmits vibration (sound) better than wood.

So look for more cold-formed steel in buildings as modular construction becomes more popular, though not discovered by homeowners until their stud finder can’t find studs and their screws don’t penetrate. But if you see it on a bridges, don’t cross. If you hear about it in a high rise, don’t get the condo.