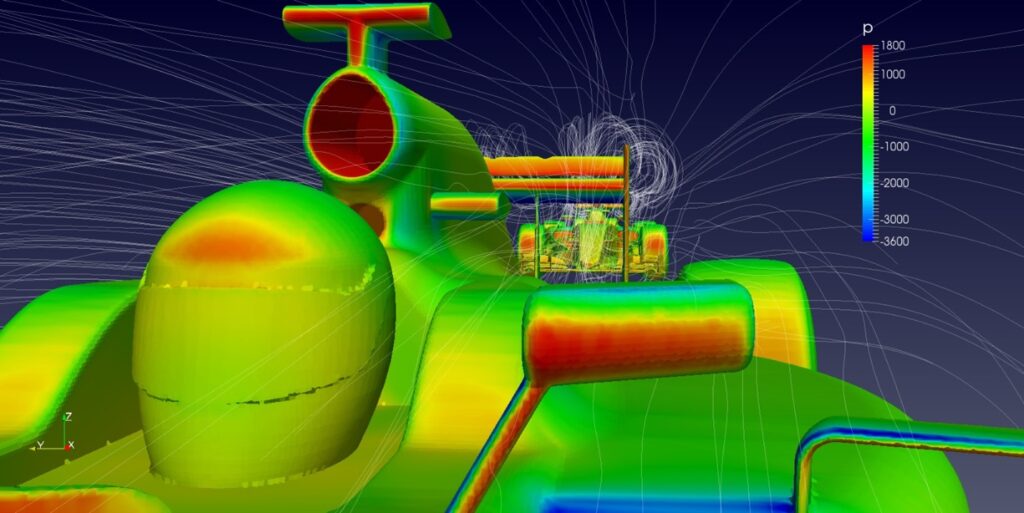

Image: Neural Concept.

A analyst studying Formula 1 race cars may want to know how a racecar design would react in the turbulent wake of the car in front of it. But if each tweak of the shape or angles of the vents requires a CFD simulation, it could take forever. But what if you could learn from previous CFD simulation results and apply what you learned to the next simulation?

Providing the changes are gradual, not radical, Neural Concept, a small Swiss firm, can do just that: predict the solution without the time and resources required for CFD simulation.

I interviewed Pierre Baqué, CEO, for an article in engineering.com published April of 2023. I was glad to see they will be exhibiting at CES 2024. The technology looked quite promising then. Now, it seems compelling.

A simulation to calculate Cd (coefficient of drag) can take 4-8 hours. With a trained neural network, it can take a tenth of a second, according to Neural Concepts. That’s more than a 100 thousand times faster?

But as was explained to me in our previous conversation, there is a catch. You can’t throw any arbitrary shape Neural Concept and have it be solved immediately. The example above relies on Neural Concept being fed a steady diet of F1 car flow simulations. If we gave it an aircraft with radically different geometry, it would not work.

Neural Concept is ideal for repetitive simulation. Airbus is a user. I imagine them using it to study a thousand what-ifs, varying winglet angles, for example.

Neural Concept claims to make short work of sifting through your simulations, learning from them, and applying what was learned to suggest potentially thousands of optimized designs. But instead of a mind-boggling array of choices, the company uses proprietary algorithms to sort them.

Look for Neural Concept in the SWISSTECH pavilion at CES 2025 at the Venetian Expo (Eureka Park Booth #61033, Level 1, Hall G ).