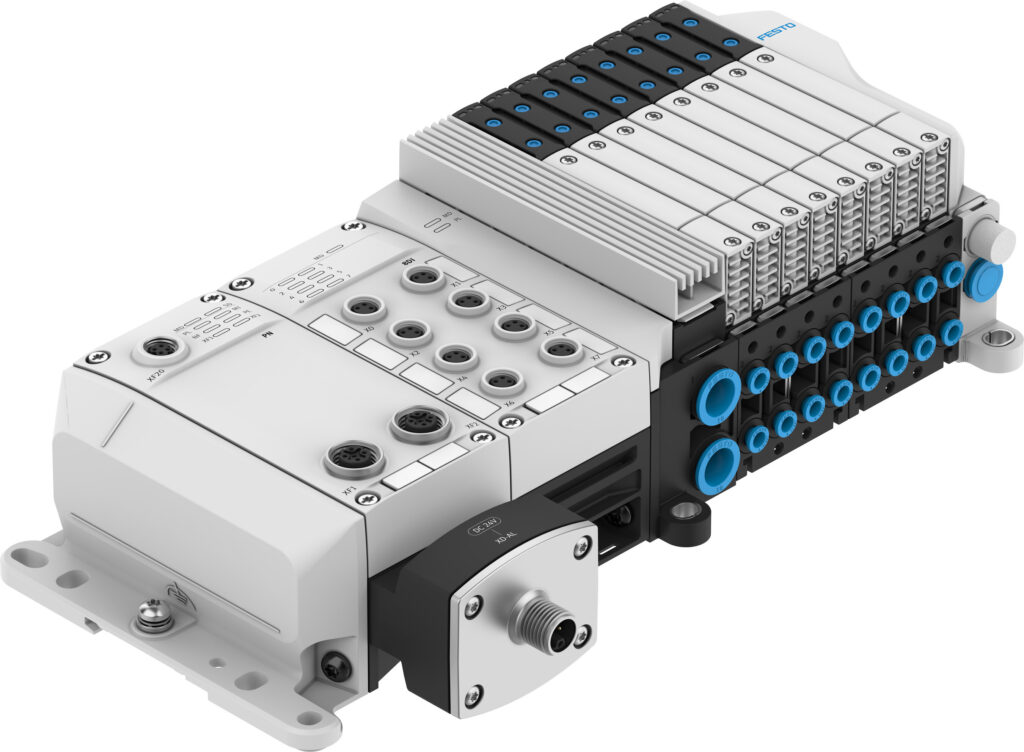

ISLANDIA, NY, Jan 21, 2025 – Festo introduces its new valve terminal, the VTUX. The VTUX can serve as I/O, remote I/O, and decentralized I/O. These durable IP65/67-rated terminals can be placed anywhere on a machine to boost performance and speed up OEM installation. VTUX modularity results in less inventory and lower overhead costs. The VTUX is set to replace Festo’s legacy terminals.

VTUX is both compact and lightweight, an advantage for end-of-arm tooling and conserving space on a machine or in a control cabinet. The terminal is built from a tough polymer, allowing use in welding environments.

The key to the VTUX’s flexibility is its modular design. For high flow rates up to 670 l/min, a high flow subbase is used and for space saving needs, the compact subbase. A single valve model can be used for both subbases, which simplifies ordering, stocking, and support. High flow and compact subbases of one or four valve positions can be mixed and matched on a terminal. VTUX terminals can have up to 128 valves with up to 128 solenoid coils. The VTUX also features vacuum capability.

The electronics side of the terminal offers the same flexibility as the pneumatics side by featuring mix-and-match modules. For example, users can add multiple analog or digital I/O modules, including I/O-Link. The modular concept continues through to the method of communication between controller and terminal. The choices include the new Festo Automation Platform (AP) for backplane speed communication in all top communication protocols. All AP-based modules appear to the control engineer to be under a single IP address that simplifies commissioning and allows smaller and less expensive PLCs to be specified. Additional communication modules include IO-Link, AP-I for decentralized I/O, and multipin connector.

VTUX terminals are assembled and tested at the Festo Regional Service Center in Mason, Ohio. They arrive ready for installation. As a key Festo product, VTUX parts are stocked worldwide to ensure quick replacements and reduce downtime. The modular design simplifies inventory, shortens training, and speeds up troubleshooting and repairs.

Source: Festo