Every year around this time, the best infrastructure projects that use Bentley Systems software (as determined by independent judges) are feted at the only black-tie awards ceremony in the industry at a conference named The Year in Infrastructure.

This year’s event is being held in Vancouver, a mere two-hour flight from SFO for yours truly.

Once again, the projects are breathtaking in their scale. I regret only that I can’t see all the finalists give their presentations. The presentations all happen in one day in parallel tracks, and the choice of which one to go to at any one time can be an excruciating decision.

Here are highlights from what I managed to attend.

Milan Style

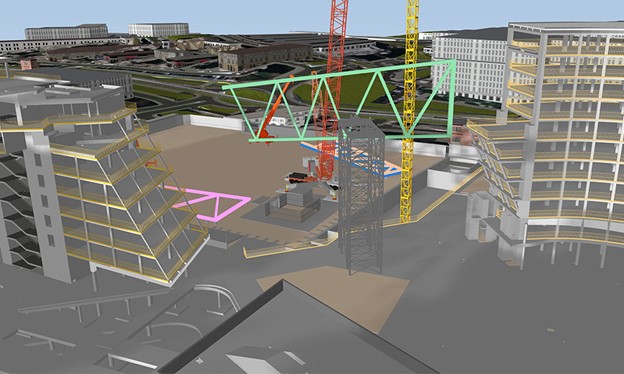

Milan is Italy’s fashion center, and you might expect its buildings to be designed with style. ENI headquarters, a curvaceous building with a fantastic sky bridge, does not disappoint. The sky bridge connects two towers, and the preassembled steelwork was so massive that physics-based animation was used to make sure cranes would not tip over as they were hoisted in place.

Webuild used Bentley’s SYNCHRO software. In addition to making sure cranes didn’t tip over, SYNCHRO created a virtual construction environment, performing clash detection and scenario analysis to visualize every step of the construction process.

Before anything was made in the field, it was made on the screen,” says Allesandro. Being able to see how everything would go together on their iPhones helped reduce rework by 90% and shrink the construction timeline from 85 by an astounding 81 days! Less time on the job also means less injuries. Webuild manage to throw a perfect game: zero injuries.

Hutama’s Phase 2A of Jakarta’s Metro

PT Hutama Karya used Bentley’s software to model Jakarta’s MRT Phase 2A, which involves building two underground stations. Hutama’s challenges included a dense urban population and geotechnical conditions. Using Bentley’s geotechnical software Leapfrog and PLAXIS for soil analysis improved soil data collection and analysis, saved the equivalent of $2.5 million. Hutama used SYNCHRO for 4D planning, ProjectWise and iTwin for digital twin collaboration and LumenRT. So much of the project was modeled digitally, making onsite inspections unnecessary 90% of the time.

To be continued…