After seeing so many releases during his time with the venerable MCAD program, what could excite Manish Kumar? Kumar, CEO of SOLIDWORKS for over two and a half years, started with SOLIDWORKS as a software developer in 1999. He may not be coding anymore, but he still keeps both hands on the software, using every excuse he can muster to use the program, such as modeling his house or desk. As a user, he can hold his own, earning the Certified SOLIDWORKS Professional (CSWP) award, which only 3% have.

SOLIDWORKS 2025 does not add all that much in the way of big feature enhancements. But we can make it faster and help you work better with others, says Kumar. He does indeed point out a handful of feature enhancements, but what excites him the most is the speed and collaboration enhancements and a new high-end package, SOLIDWORKS Ultimate

How much would that be? If you are asking, you probably can’t afford it. Expect it to cost significantly more than SOLIDWORKS Premium, which sold for $8,395 (perpetual license) or $4,848 a year.

Here is a more detailed list of what excites Manish the most about SOLIDWORKS 2025 based mainly on a post attributed to him on the SOLIDWORKS blog.

1. Platform Collaboration and Performance

One of the most significant themes in SolidWorks 2025 is enhanced collaboration through platform integration. The update introduces features that make it easier for teams to work together on complex projects. Real-time notifications and multi approval timestamps are meant to allow users to track project status and approvals efficiently. These enhancements aim to streamline workflows, ensuring that all stakeholders are up-to-date on project developments. Kumar emphasizes that the goal is to “deliver a seamless customer experience” by focusing on performance and integration.

2. Selection Accelerators

A complex design often involves selecting multiple components or features for fillets or chamfers. This can be time-consuming. SolidWorks 2025 addresses this by introducing Selection Accelerators, allowing users to make more automatic selections. Selection Accelerators could increase design process efficiency by providing options to select similar items based on criteria like size, location, or feature type. Kumar mentions that this feature “accelerates the design process,” allowing users to focus more on creativity than routine tasks.

3. New History Tab

The new History tab in SolidWorks 2025 provides a detailed timeline of all changes made to a model. This feature lets users see who made changes and when making it easier to track the design process and identify potential issues. The History tab is not just a record-keeping tool; it’s essential for maintaining design integrity and ensuring all team members are on the same page.

What 4. Enhanced Plastic and Sheet Metal Design

SolidWorks 2025 introduces enhanced plastic and sheet metal design tools, catering to industries where these materials are prevalent. The update offers more control over design elements, such as wall thickness, rib design, and bend allowances. According to Kumar, the improved tools aim to “provide more flexibility and precision” in designing components.

5. Interference Detection in Large Design Review Mode

Large assemblies can be challenging to manage, especially when detecting interferences. SolidWorks 2025 addresses this with an enhanced interference detection feature in Large Design Review mode. This feature allows users to identify and resolve interferences in large assemblies without opening the entire model, saving time and computational resources. This enhancement is crucial for industries that work with complex assemblies, as it helps to “ensure that the final product is free of errors,” as Kumar puts it.

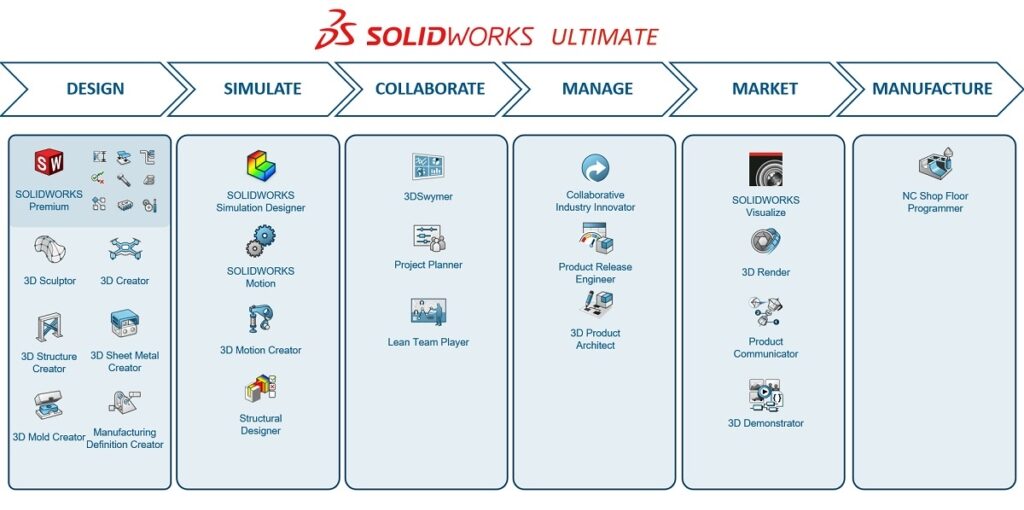

6. SOLIDWORKS Ultimate Package

Kumar introduced the SOLIDWORKS Ultimate package, which eclipses the SOLIDWORKS Premium package by adding more collaboration, simulation, and manufacturing features and capability. The Ultimate package provides access to advanced features such as simulation, electrical design, and manufacturing planning, all within a single platform. This integration aims to provide a “one-stop solution” for designers and engineers, reducing the need for multiple software tools. See the complete feature comparison in a PDF here. Pricing for SOLIDWORKS Ultimate was not available.

7. Real-Time Collaboration Tools

SOLIDWORKS 2025 introduces several enhancements to improve collaboration. One key feature is the ability for file-sharing participants to add comments directly to each shared file, facilitating better communication

with external users. This can be enabled through the “Collaboration Options,” allowing external users to contribute comments and even replace internal usernames with generic names for privacy on the shared file page. Additionally, SOLIDWORKS provides options for a multi-user environment, including enabling a read-only mode to check if other users have modified files. This ensures that changes made by others are detected and communicated, helping avoid conflicts during collaborative work

8. Improved Performance and Stability

Performance and stability are always a priority in software development and SolidWorks 2025 is no exception. The update includes various under-the-hood enhancements that improve the software’s responsiveness and reduce the likelihood of crashes. These improvements are particularly noticeable when working with large assemblies or complex models, providing a smoother user experience. Kumar notes that these performance enhancements “make SolidWorks more reliable and efficient.”

9. Advanced Simulation Capabilities

In SOLIDWORKS Simulation 2025, there are notable advancements aimed at enhancing the simulation process. Bonding interactions now handle offset surfaces more effectively, ensuring more precise results. The edge weld and pin connectors have been refined for improved accuracy. Users can also exclude multiple bodies from analyses, making simulations more efficient. A new general spring connector has been introduced to accommodate a variety of surface connections. Additionally, surface bonding improves

geometry correction, reducing meshing times for assemblies with multiple identical parts.