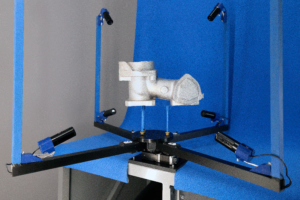

OWINGS MILLS, MD, Mar 11, 2025 – Direct Dimensions has announced the launch of the Part Automated Scanning System (PASS). PASS was designed to improve the process of digitizing physical objects by providing fast, accurate scanning. It can scan an object in approximately two minutes without requiring manual part flipping, scanner repositioning, or complex software adjustments. This efficiency reduces costs by enabling large-scale digitization in a reasonable timeframe, without requiring specialized technicians.

Key Features of PASS:

- High Throughput: Capable of scanning objects up to 16″ x 16″ x 16″ in volume, PASS captures detailed 3D data in about two minutes per item.

- Exceptional Accuracy: With precision levels reaching as low as +/- 10 microns, PASS ensures that digital replicas are virtually identical to their physical counterparts.

- Automated Workflow: The system’s automation reduces the need for manual intervention, allowing for the efficient digitization of extensive inventories.

- Versatile Applications: PASS is ideal for inventory management, e-commerce, digital catalogs, virtual galleries, and part inspection, among other uses.

“The introduction of PASS marks a significant milestone in automated 3D scanning technology,” said Michael Raphael, president and founder of Direct Dimensions. “Our goal was to create a system that not only delivers high-quality digital replicas but also integrates seamlessly into various workflows, empowering companies to easily harness the full potential of digital twin technology.”

Functional Specifications:

- Maximum Object Volume: 16″ x 16″ x 16″

- Accuracy: <1 mm, as low as +/- 10 microns

- Capture Time: Approximately 2 minutes

- Post-Processing Time: Approximately 7 minutes (unattended, in background)

- Output: OBJ mesh file, JPG texture file, and customizable metadata fields

Physical Specifications:

- System Footprint: 9 ft x 5 ft x 8 ft tall, plus room to stage objects

- Power Requirements: One 15-amp AC outlet

- Lighting: Integral LED light and texture projectors

- Environment: Suitable for small rooms with normal office lighting

- Safety Features: Turntable emergency-stop and continuous eye-safe lighting

The versatility of PASS extends across various industries. For example, museum curators can digitize entire collections, making artifacts accessible to researchers all around the globe. Manufacturers can create digital twins of components for quality assurance and inventory management. E-commerce platforms can provide customers with interactive 3D models of products, developing the online shopping experience.

Direct Dimensions has seen successful implementations of PASS in sectors like defense, where a contractor used it to digitize maintenance parts, improving supply chain management and reducing downtime. Similarly, cultural institutions have employed PASS to create virtual galleries, enabling global audiences to explore exhibits remotely.

“PASS makes 3D possible for everyone, everywhere,” added Raphael. “By removing the complexities traditionally associated with 3D scanning, we’ve opened the door for organizations of all sizes to embrace digital transformation.”

Direct Dimensions is also a trusted reseller of 3D scanning products, including those from manufacturers such as Artec 3D and Faro. The company’s R&D department develops custom scanning solutions to address specific industry needs, providing clients with tools for 3D digitization challenges.

Source: Direct Dimensions

About Direct Dimensions

![]()

Direct Dimensions, Inc., founded in 1995, specializes in advanced 3D scanning and industrial dimensional measurement solutions. With over 25 years of experience, the company offers services such as 3D imaging, modeling, and rapid prototyping. They serve a diverse range of industries, including engineering, manufacturing, federal/DOD, art, museum, sculpture, architecture, construction, VFX, entertainment, research, and development. Headquartered in Owings Mills, MD, Direct Dimensions has an estimated annual revenue of $2.9 million and employs approximately 36 people.