Hexagon has acquired Geomagic software from 3D Systems Corp. This addition provides advanced tools to streamline tasks like collecting and reverse engineering 3D measurement data. The tools support product development and CAD workflows across the lifecycle.

Integrated into its manufacturing intelligence division, the Geomagic software solutions will be supported and sold to the discrete manufacturing market, complementing portfolios in Hexagon’s mining and construction markets. The suite comprises measurement and quality control software, mesh and surface model creation, and parametric scan-to-CAD workflows for reverse engineering.

President of Hexagon’s manufacturing intelligence division, Josh Weiss commented, “We are delighted that Geomagic has joined Hexagon. The software and the team are pioneers in the creation of powerful and intuitive scan-based reverse engineering, inspection and design tools. The suite is imperative to manufacturing industry success, and provides the experience that their global customers, partners and hardware OEMs need.”

“We will continue to support all hardware and software partnerships for Geomagic customers. We will invest in developing and supporting this software with our considerable expertise and IP to offer our portable metrology device users greater productivity and new capabilities.”

A key aspect of the Geomagic suite is that it works with any 3D scanner or portable CMM. The software supports reverse engineering and metrology workflows with 3D scanning devices from optical, laser and LiDAR scanning devices from any vendor, and Hexagon will continue to offer all customers access to the software portfolio and support native CAD and PMI data import from Dassault CATIA, PTC Creo, Autodesk Inventor, Siemens NX, and Dassault SOLIDWORKS.

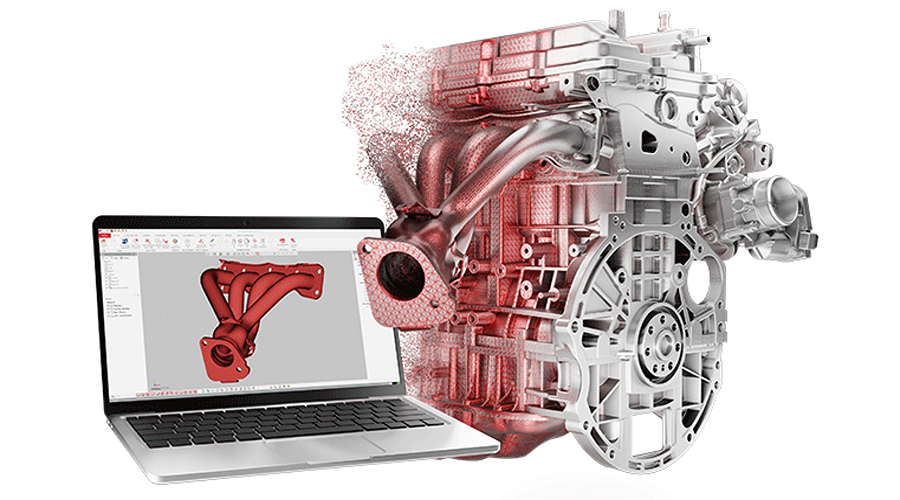

Geomagic Design X is a 3D scan-to-CAD solution used for reverse engineering and documenting physical parts. Users can reverse engineer data from any scanner with intuitive guided workflows that provide conversion and recreation of parametric CAD. Design X features automated mesh-to-surface functionality where needed – for example, in mould and die applications – and complements all CAD software workflows.

“3D scanning allows us to do things we couldn’t do before because of the complexity of parts. With Geomagic Design X we can create models of parts that were previously difficult to model. Once we got the training, we could model much faster than before.” Fabien Brunet, tool design technician, Schneider Electric.

Geomagic Control X simplifies 3D scan-based inspection with software designed to analyze scan data and generate reports. It includes robust workflow automation and ensures accuracy validated with NIST, PBT, and NPL standards organizations. Hexagon plans to enhance the software by integrating its GD&T libraries.

“Doing reports can be very painful, so I looked through the tools Geomagic Control X had to offer and discovered the reporting functionality. It reduced the time I spend on reporting by around 70%. Before I needed about eight hours to make the report, and with Geomagic Control X it takes just three.” Hazim Abueideh, quality control analyst, air up GmbH.

Other software solutions in the Geomagic suite include Geomagic for SOLIDWORKS, which enables SOLIDWORKS CAD users to reverse engineer scan data inside their native SOLIDWORKS workspace, Geomagic Wrap, which provides accurate NURBS surface creation from large point clouds and meshes, and Geomagic Freeform – an organic design solution with applications across personalized healthcare, orthotics & prosthetics and industrial design.

Hexagon’s global hardware customers will benefit from integrated reverse engineering and metrology capabilities, with scanning support from its range of sensors, including the recently launched SmartScan VR800, ATLASCAN Max, and MARVELSCAN products.

Source: Hexagon

About Hexagon

Hexagon AB, established in 1975, specializes in digital reality solutions integrating sensors, software, and autonomous technologies. Headquartered in Stockholm, Sweden, Hexagon operates in over 50 countries and employs approximately 24,800 people. The company serves various industries, including construction, mining, agriculture, aerospace, automotive, defense, and manufacturing. Its offerings encompass reality capture measurement, intelligent positioning, situational intelligence, and industrial design solutions. In 2023, Hexagon reported annual revenues of approximately €5.44 billion. Since 2000, Hexagon has completed over 170 strategic acquisitions, enhancing its position in digital transformation and enabling clients to utilize data for improved efficiency, productivity, quality, and safety across various applications.

About 3D Systems

![]()

Founded in 1986 by Charles “Chuck” Hull, 3D Systems is a founding force in the additive manufacturing industry, credited with inventing stereolithography (SLA) and commercializing the first 3D printer, the SLA-1. Headquartered in Rock Hill, SC, the company offers various 3D printing solutions, including hardware, software, and materials. These cater to diverse industries such as aerospace, automotive, healthcare, dental, and consumer goods, facilitating applications from prototyping to full-scale production. In 2023, 3D Systems reported revenues of $488 million, reflecting its role in advancing manufacturing technologies. As of December 31, 2023, 3D Systems employs approximately 1,925 individuals globally. The company’s global presence includes offices, manufacturing facilities, and Customer Innovation Centers, all dedicated to helping businesses integrate 3D printing into their operations for enhanced efficiency and innovation.