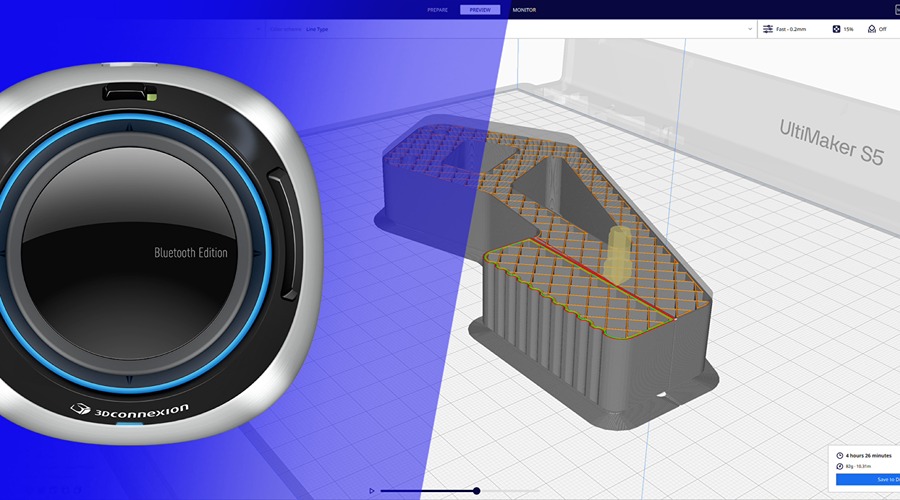

Monaco, Apr 11, 2025 – 3Dconnexion has announced an enhancement for 3D printing professionals by integrating 3Dconnexion device support in UltiMaker Cura. The development offers users an intuitive and immersive 3D navigation experience, enhancing precision and efficiency in 3D model slicing and preparation.

3Dconnexion’s input devices, including the SpaceMouse, are designed to improve 3D model navigation and user comfort. With this integration, UltiMaker Cura users gain precise control over model positioning, orientation, and preparation during the slicing process.

“Integrating 3Dconnexion devices with UltiMaker Cura ensures a new level of efficiency, allowing professionals and enthusiasts alike to experience enhanced precision in their 3D printing workflow,” said Robert Stadie, product manager at 3Dconnexion. “By enabling seamless 3D navigation in Cura, we are closing the gap between design and print preparation, creating a more intuitive and productive experience for our users.”

For years, 3Dconnexion has provided input devices for engineering, architecture, and design professionals, focusing on precision and workflow compatibility. Its devices are tailored to support integration across multiple software platforms.

“We are excited to bring 3Dconnexion device support to UltiMaker Cura,” said Mariska Maas, product manager for Cura. “This integration empowers our users with precise control and an enhanced experience, ensuring they can fine-tune their models with the same level of detail and fluidity as they do during the design phase.”

Enhanced 3D Printing Workflows

UltiMaker Cura allows users to prepare their models with ease and precision. Adding 3Dconnexion devices will enable professionals to use the same precise control during slicing and preparation as in the design phase.

Key benefits of this integration include:

- Precision navigation: Users can pan, zoom, and rotate models with ease, supporting efficient interactions and helping reduce reliance on keyboard shortcuts or repeated mouse actions.

- Efficiency & workflow speed: The SpaceMouse allows users to navigate with one hand while using the other for adjustments. This simplifies model inspection, support generation, and orientation changes to improve print setup.

- Ergonomic & customizable: A two-handed workflow can help lower wrist strain, while programmable buttons offer access to common Cura functions like view switching, slicing, and layer previewing, supporting an efficient setup.

- Seamless integration across 3D software: The device supports a consistent user experience across design applications, including Fusion, SolidWorks, Blender, and UltiMaker Cura.

The integration is available as of date. Users can improve their 3D printing workflows by updating UltiMaker Cura and connecting their 3Dconnexion devices.

Source: 3Dconnexion

About 3Dconnexion

![]()

3Dconnexion, established in 2001 as a subsidiary of Logitech, specializes in developing 3D input devices designed to enhance the efficiency and comfort of professionals working with 3D applications. Their product lineup includes 3D mice and controllers facilitating intuitive navigation and control within CAD, PLM, GIS, and DCC environments. For industries like engineering, architecture, and digital media, 3Dconnexion’s tools are integral to workflows requiring precise 3D manipulation. Headquartered in Silicon Valley, CA, the company also maintains offices in Munich, Paris, London, Tokyo, and Shanghai, reflecting its global reach. With an estimated annual revenue of $15.5 million and a workforce of approximately 100 employees, 3Dconnexion continues to support a growing base of over 325,000 professionals worldwide, emphasizing innovation in 3D navigation technology.

About UltiMaker

![]()

UltiMaker, established in 2011 by Martijn Elserman, Erik de Bruijn, and Siert Wijnia, is a key producer of 3D printers. The company focuses on fused filament fabrication (FFF) technology, offering 3D printers, software, and materials. Its range of products includes models like the Ultimaker S5, S3, and Ultimaker 3 series. These are used in automotive, architecture, healthcare, education, and small-scale manufacturing industries. The company is based in Geldermalsen, Netherlands, and expanded globally by merging with MakerBot in 2022. As of 2024, UltiMaker has around 220 employees across Europe, North America, and Asia. They report approximately $75 million in annual revenue and serve thousands of customers worldwide.