DETROIT, MI, Apr 16, 2025 – Materialise has unveiled the 2025 Magics release alongside strategic partnerships with Raplas and One Click Metal at RAPID+TCT 2025. The announcements address key challenges in AM design limitations, part costs, and manufacturing speed to advance the use of AM in industries like aerospace, healthcare, and automotive. The company reports that the combined solutions of the new Magics release with nTop implicit geometries overcome traditional AM design challenges by reducing build preparation time from days to seconds while maintaining design precision. This new feature in Magics, combined with Materialise’s updated build processors, improves support for printing complex parts that could not be printed before.

“As additive manufacturing transitions from a niche technology to a cornerstone of modern manufacturing, the need for intelligent, integrated software is more critical than ever,” said Udo Eberlein, vice president of software at Materialise. “We are listening closely to the demands of the market and evolving our software portfolio into an integrated range of solutions that work together with other manufacturing tools. By addressing challenges such as cost, scalability, and precision, we are laying the foundation for seamless workflows that connect additive manufacturing to broader production ecosystems.”

Unveiling the 2025 Magics release: breaking design barriers and optimizing costs

The new release delivers practical solutions for challenges in polymer and metal 3D printing. It offers implicit modeling capabilities, support generation tools, and workflow integration.

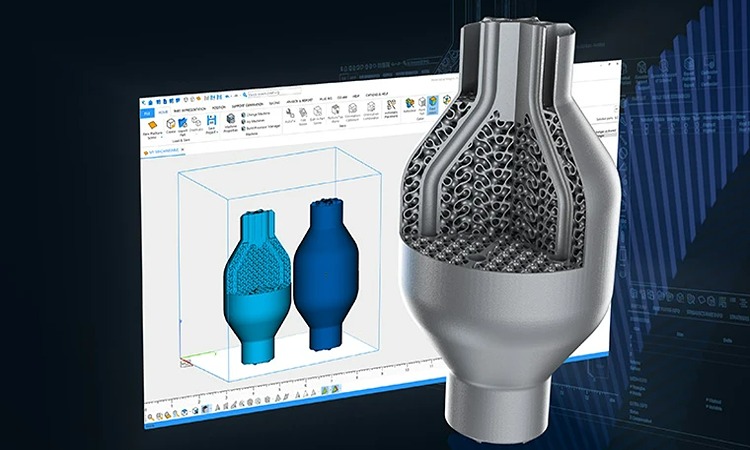

nTop implicit geometries integration

Magics supports processing nTop implicit geometries without requiring mesh conversion, reducing preparation time for complex parts. Paired with the updated slicing capabilities of Materialise’s next-gen build processors, it enables the design and production of parts previously limited by data and memory constraints.

The ADDITIVE INTELLIGENCE department at DMG MORI Technium Europe took part in the 2024 Early Access Program launched by Materialise and nTop. Building on their previous success redesigning the AKZ FDS adapter for AM, a part of a CNC machine tool, the DMG MORI design team used the integration of Magics and nTop to process a high-performance geometry file in seconds, compared to days before. The integration of these two software programs improves additive manufacturing efficiency and increases innovation potential in 3D printing workflows.

“Before joining the Materialise and nTop Early Access Program, meshing complex geometries consumed days of work. Now, with the new integration into Magics, it takes seconds. This integration hasn’t just streamlined our workflow – it fundamentally enhances our ability to design for additive manufacturing. Collaborations like this are exactly what our industry needs to overcome technical barriers and push additive manufacturing toward its full potential,” says Martin Blanke, project engineer additive manufacturing, DMG MORI Technium Europe GmbH.

BREP import and processing

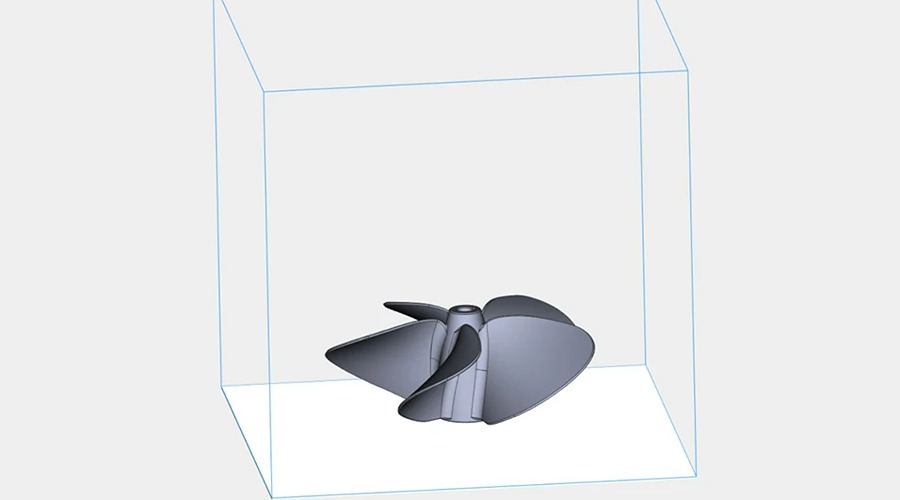

The update adds BREP processing, allowing users to handle CAD files directly in Magics. This helps maintain part quality, speeds up work, and reduces the need for manual fixes. Ideal for CNC workflows and users of SLS, MJF, and metal LPBF, it streamlines operations by supporting functions like measurements, wall thickness analysis, nesting, and STEP file export for use in CAM and CAD software.

Optimizing part costs

With post-printing accounting for 40 – 60% of total costs, the latest Magics offers optimizations for build preparation workflows and support generation. It reduces material use and post-processing needs while maintaining high-quality output. Key features include:

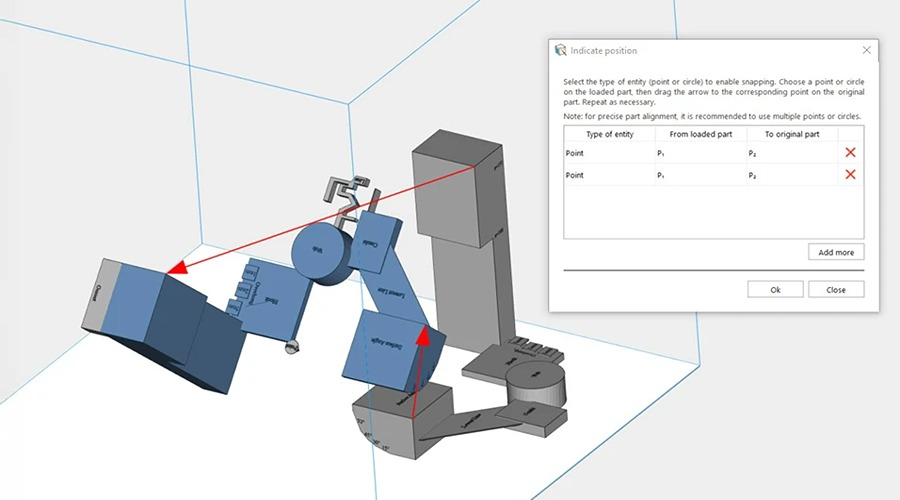

- Replace Part and Transfer Support: Designed for series production and prototyping, it facilitates design interactions for NPI and product improvements by transferring support when using the Replace Part function, reducing repetitive work, human error, and lead times.

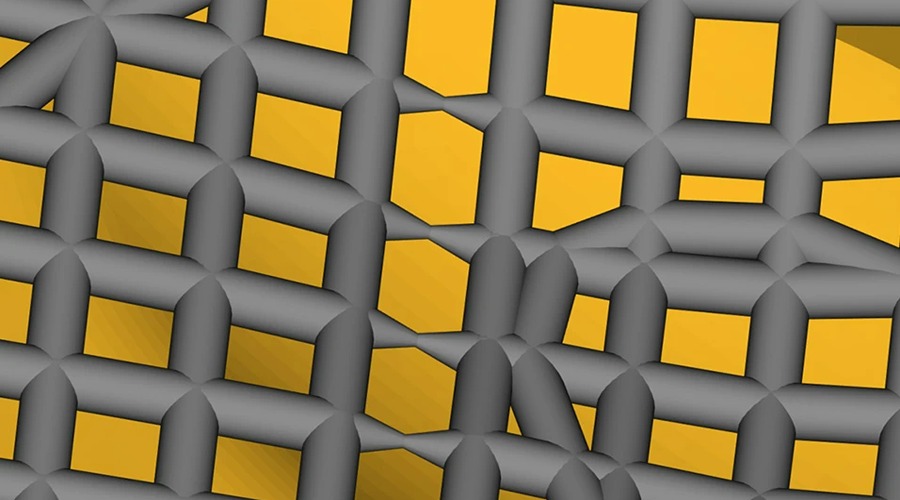

- Self-Supporting Shell and Honeycomb: Minimize support in complex areas with self-supporting volumes, simplifying removal and reducing post-processing efforts. Designed for LPBF, it also benefits other technologies, enabling precision-grade parts with fewer supports.

The Magics update brings changes that make the software easier to use. It improves how the system handles graphics and memory, helping users work efficiently. Video memory use drops by up to 40% for marked mesh parts. The update also speeds up tasks like Extrude (by 70%) and Perforator (by 50%). The Magics release will be commercially available in May 2025.

Accelerating AM: pushing print speed and performance to the next level

Materialise announces two next-generation build processors through partnerships with Raplas and One Click Metal. These advancements enhance additive manufacturing capabilities for large and mid-market production.

“By combining Raplas’ tailor-made SLA 3D printing technology with Materialise’s advanced Build Processor, we are addressing inefficiencies of legacy systems. This partnership has already demonstrated remarkable results, including a 30 – 40% increase in printing speed, enhanced part quality, and minimum post-processing requirements,” said Richard Wooldridge, CEO of Raplas. “Together, we are empowering production environments for faster, more accurate end-use parts, advancing applications in the medical, automotive, and aerospace sectors, and technologies such as investment casting.”

Earlier in March 2025, Materialise announced a build processor integration with One Click Metal to support growth in the mid-market 3D printing sector. This collaboration meets the rising demand for solutions that balance affordability and performance, offering flexible options for startups and established facilities. By integrating Materialise’s build processor to One Click Metal’s system, users gain control over production processes, streamline operations, and maintain consistent quality.

“Materialise’s strategy is to enable the next generation of additive manufacturing by combining advanced software with diverse hardware platforms. Collaborations with Raplas and One Click Metal and the launch of the 2025 Magics release reflect our commitment to supporting the full spectrum of AM production. These solutions empower customers to save time, reduce risks, and lower costs, supporting successful AM builds from start to finish,” stated Bryan Crutchfield, vice president and general manager of Materialise North America.

Source: Materialise

About Materialise

Materialise is a provider of 3D printing software and services, enabling digital manufacturing across a various industries including healthcare, automotive, aerospace, and consumer goods. Founded in 1990 and headquartered in Leuven, Belgium, the company has over three decades of experience in additive manufacturing. Materialise offers a comprehensive software suite that includes Magics for data preparation, as well as build processors and cloud-based solutions that integrate seamlessly with 3D printers and design platforms. In the medical field, it delivers patient-specific surgical planning and anatomical models, while its industrial solutions support prototyping, tooling, and production applications. The company also offers engineering services that assist organizations in optimizing designs for additive manufacturing. As of 2024, Materialise reported an annual revenue of approx. $265 million. With a global presence and continued investment in R&D, Materialise remains at the forefront of driving innovation in the 3D printing ecosystem.

About RAPLAS

Raplas Technologies Ltd is a UK-based manufacturer specializing in large-format stereolithography (SLA) 3D printers designed for industrial production. Established in 2018, the company operates its headquarters in London, with manufacturing facilities near Cardiff, Wales, and R&D centers in Wales and Germany. Raplas serves various industries, including aerospace, automotive, medical, dental, and education, by providing open-platform SLA systems that support a wide range of commercial resins. Their product lineup includes models like the PR450, PR700, and PR800, catering to diverse production needs. Notably, Raplas has collaborated with BAE Systems on defense projects and participated in initiatives like the “Made Smarter Innovation” program to advance sand casting technologies.

About One Click Metal

![]()

One Click Metal, founded in 2019 and headquartered in Tamm, Germany, is a subsidiary of INDEX Werke. The company specializes in providing accessible and affordable 3D metal printing solutions, particularly for small and medium-sized enterprises (SMEs). Their BOLDseries system utilizes laser powder bed fusion (LPBF) technology and includes components like the MPRINT printer and MPUREpro unpacking and sieving station, designed to simplify the metal additive manufacturing process. Serving industries such as automotive, aerospace, medical, dental, and education, One Click Metal aims to democratize metal 3D printing by reducing complexity and cost barriers. The company continues to expand its global presence through partnerships in regions like North America, India, and South Korea.