WESTERVILLE, OH, May 5, 2025 – ABB has signed a Memorandum of Understanding (MoU) agreement with Raumaster Paper to jointly explore integrated winder solutions in the US, helping paper mills enhance operational efficiency and extend the lifecycle of existing equipment. ABB will contribute automation, system drives, and digital expertise to the partnership, integrating its control technologies with Raumaster Paper’s paper mill finishing equipment.

Paper mills face increasing pressure to boost efficiency within limited budgets. This partnership supports modernization through selective upgrades to control and mechanical systems. Integrating Raumaster Paper’s winder designs with ABB’s automation enables faster commissioning, simplified operations, and improved operational safety for legacy assets.

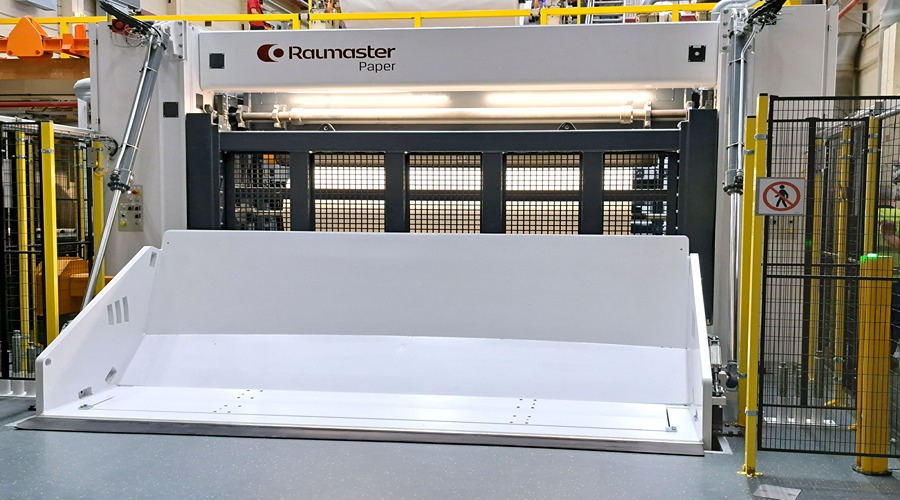

Raumaster has over 40 years of experience designing and manufacturing machinery, including paper mill finishing equipment. The company has delivered more than 110 high-capacity winders and rewinders worldwide. With a presence in Europe, Asia, and a growing footprint in North America, it offers adaptable solutions that support performance and reliability in the pulp and paper industry.

ABB’s drive control solutions for winders are deployed in over 400 installations worldwide. This collaboration provides an integrated control package compatible with ABB’s automation system, including ABB Ability System 800xA, motors, and drives. The solution supports operation, maintenance, and performance monitoring of finishing processes.

“Our customers rely on high-performance, reliable winder solutions to keep their operations running smoothly,” said Pekka Leino, managing director at Raumaster Paper. “They also need future-ready systems that integrate seamlessly with the latest automation technologies. By working with ABB, we are bringing together decades of experience in winder design with industry-leading control solutions, creating a compelling, operator-friendly package for paper mills worldwide. This collaboration will help mills not only optimize efficiency and quality output but also extend the life of their equipment.”

“Paper mills today need solutions that not only improve productivity but also make life easier for their operators – especially in an industry where mills are working hard to maximize the performance of existing assets,” said Shankar Singh, global product line manager at ABB. “With our globally proven drive control solutions for winders, we’re providing mills with a smarter, more connected approach to finishing operations. Partnering with Raumaster Paper allows us to offer a seamless package that combines best-in-class automation with trusted mechanical expertise, ensuring mills can modernize efficiently and cost-effectively.”

The agreement outlines a framework for standardizing winder drive control solutions, machine control systems, and safety features. It aligns ABB’s automation technologies with Raumaster’s winder technology. The companies will also work together on retrofits and new winder installations. This joint effort supports ABB and Raumaster Paper’s commitment to help the paper industry improve efficiency and sustainability.

Source: ABB

About ABB

ABB is a global technology leader in electrification and automation, headquartered in Zürich, Switzerland, and Västerås, Sweden. Formed in 1988 through the merger of Sweden’s ASEA and Switzerland’s Brown, Boveri & Cie, the company traces its roots back to 1883. ABB operates in over 100 countries, serving industries such as utilities, transportation, infrastructure, and manufacturing. Its offerings include robotics, industrial automation, electrification products, and motion solutions. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. As of 2024, ABB reported revenues of approximately $33 billion and employed around 110,000 people worldwide. The company operates in over 100 countries, across Europe, Asia, the Middle East, Africa, and the Americas. ABB focuses on innovation and sustainability by investing in research and development to support the shift toward a more resource-efficient future.

About Raumaster Paper

![]()

Raumaster Paper Oy, established in 2003 as a subsidiary of Raumaster Oy, specializes in providing paper finishing systems, pulp bale handling, and automated warehouse solutions for the pulp and paper industry. Headquartered in Finland, the company operates additional facilities in Pori and Valkeakoski. With a workforce of approximately 100 employees, Raumaster Paper achieved a turnover of €35 million in 2024. Its product portfolio includes roll handling, wrapping, core handling and splitting, winders and rewinders, coating and laminating lines, and storage solutions like the Mastergrip system. The company serves clients in Europe, Asia, and North America, offering both new installations and modernization services to enhance operational efficiency and safety in paper mills. Raumaster Paper is part of the Raumaster Group, which has a broader focus on material handling systems for energy and wood processing industries.