If you are creating 3D models with CAD, you are depending on geometry kernels such as Parasolid, ACIS, Granite, CGM, others of that ilk, or their derivatives. You don’t know what you are missing.

The problem lies not in what you can model but what you cannot. You can certainly model almost all machine parts and structures, those that are straight or round, true, symmetric… attributes that define your idea of perfection. But pull your head out of your screen for a second. Go outside, look around at the world. Is anything round, true or symmetric?

The natural world, with its living cells, flowers, trees, rivers, coastlines… is anything but perfect geometry. No wonder we have such a difficult time modeling it. Our modeling tools are based on perfect geometry.

You have to search long and hard to find anything that comes close to what you would consider perfect in Nature. Maybe crystals? Honeycombs with their hexagonal cells? Look closely. Honeycombs are far from perfect hexagons.

What do you expect? Honeybees don’t have our tools, our straight edges, levels, plumb lines, CAD, CNC… the tools of our perfection.

Have our tools become our masters, confining us to a design prison, limiting our creations to what they can design and build?

Back to Nature

Frank Gehry broke free of the design prison and found fame with buildings with fantastically curvaceous shapes, such as the Walt Disney Concert Hall in Los Angeles (pictured above). It couldn’t have been easy. Gehry had to bend CATIA, a CAD program created to design aircraft, to his will. Another breakout was performed by George Nakashima, a Japanese-inspired artist whose furniture designs incorporated the natural shape of wood. No CAD program could manage that.

While there are several excellent surface modeling programs able to make organic shapes, notably Autodesk’s 3ds Max and Alias as well as Rhino by Robert MacNeel, they have found little favor with mechanical designers, engineers or architects and remain the tools of game character makers, creators of mystical worlds with dragons and CG (computer graphic) artists. The disdain is mutual: CAD programs are shunned by “creatives.” Buzz Cross, then VP of Autodesk, described an event with the “pony-tails on one side of the room and pocket-protectors on the other.”

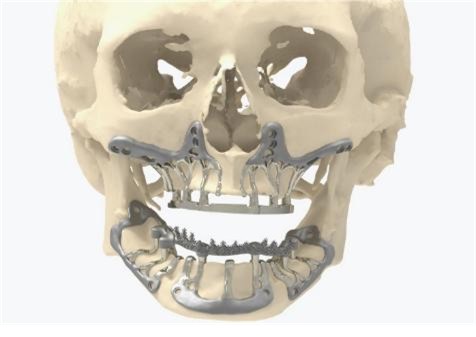

It’s at the interface of the natural and manmade world that can be the most problematic. Here we have my beloved iPhone. Never mind that its design does not conform at all to my hand. I am bothered daily by the Buck Institute, an I.M. Pei masterpiece which, nevertheless, sits incongruously up in the hills of Novato. However, some matters are far more serious, such as the reconstruction of a jawbone with a titanium implant. Modeling such a prosthetic demands an irregular shape. That usually requires making a mesh model.

Nature abhors a straight line and doesn’t do meshes. The current popular CAD geometry engines may be trying to adapt to a world of irregular shapes with its meshes and point clouds, but they are not having an easy time of it.

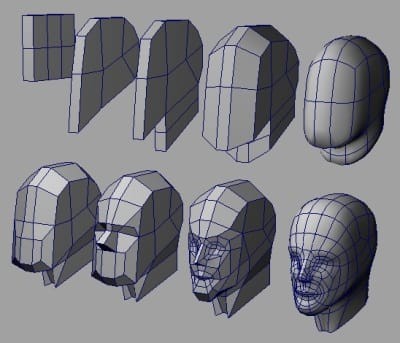

So what is an engineer to do when confronted with an ergonomic requirement in product design at work or making a live edge table in their home workshop? No, I don’t want to buy and learn Alias, 3D Studio or Rhino. They would be foreign languages, unlike the CAD programs I am familiar with, and life is short. However, cajoling a CAD surface modeler is also a formidable undertaking. Moreover, surface modelers, whether they be traditional NURBS (non-rational B-splines) modelers or the new breed of modelers known as subD (subdivision) modelers, have their faults.

When a surface is based on splines, it is modified by tweaking the splines. The shape is only influenced by the spline, not defined by it. So, good luck in getting the shape to any measure of exactness.

With a subD (subdivision modeler), you could start with simple shapes and push and pull them to try to get the exact shape you want. The shape could be curvy and organic. Continually subdividing shapes increases the model’s complexity, making it cumbersome. You can also make it discontinuous, or no longer “watertight.”

“Ease of use is definitely better with subD than with NURBS-based systems but this comes at a cost of precision and exactness,” says Tassos Hadjicocolis, co-founder and CEO of Phenometry. “As you have no direct control on your shape’s curves/edges and are working only through control cages, you can only approximate the exact shape no matter how much you iterate or subdivide.”

I am introduced to Hadjicocolis in Coventry, U.K., by CAD legend Mike Payne, as the DEVELOP3D Live 2025 winds down. Hadjicocolis tells me about his company, Phenometry, which has created Phi, a 3D surface modeling program like no other. It can model natural shapes easily and exactly. Hadjicocolis is Greek and the company is based in Athens, Greece. I had better look into this. It would not be the first time a Greek has made a significant contribution to geometry.

Enter Phi

Modeling organic shape is something CAD programs have never done well. The best of them offer us NURBS for this purpose. But NURBS have their limitations.

“NURBS-based systems, though precise and able to produce top quality models, are a nightmare to use even for experts,” says Hadjicocolis. “I keep being surprised by how much effort is being spent by designers to try and tame the underlying infrastructure so it doesn’t break. They have to fight against it all the time for anything more than a surface of revolution or swept surface.”

CAD users also use Lofting, the process of creating 2D profiles, fitting them to splines in the 3rd dimension to create a surface.

“Not being able to visualize your design in 3D till the last stage and then often having to start from scratch for any non-trivial change does not exactly fit the idea of creative process,” says Hadjicocolis.

Obviously, what is needed is a surface modeler explicitly created for mechanical designers that offers direct and exact shape manipulation without the cumbersome growing complexity.

That may describe a relatively new surface modeler, Phi, to the letter.

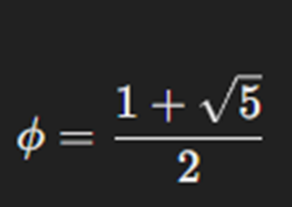

Pardon the pun. Phi, or Φ, is the 21st letter of the Greek alphabet. Phenometry, the maker of Phi, is based in Athens, Greece.

Phi is the ratio of the sum of two quantities over the larger quantity. It can be expressed by the formula below and approximated as 1.618.

The Golden Ratio is related to the Fibonacci spiral, which occurs naturally and marvelously in nature and is most striking and perfect in the shell of the chambered Nautilus (lower right, above). It has been found in manmade shapes from antiquity. It has been used by artists and architects, notably Salvador Dali and Le Corbusier,

Fee Phi Fo Fun

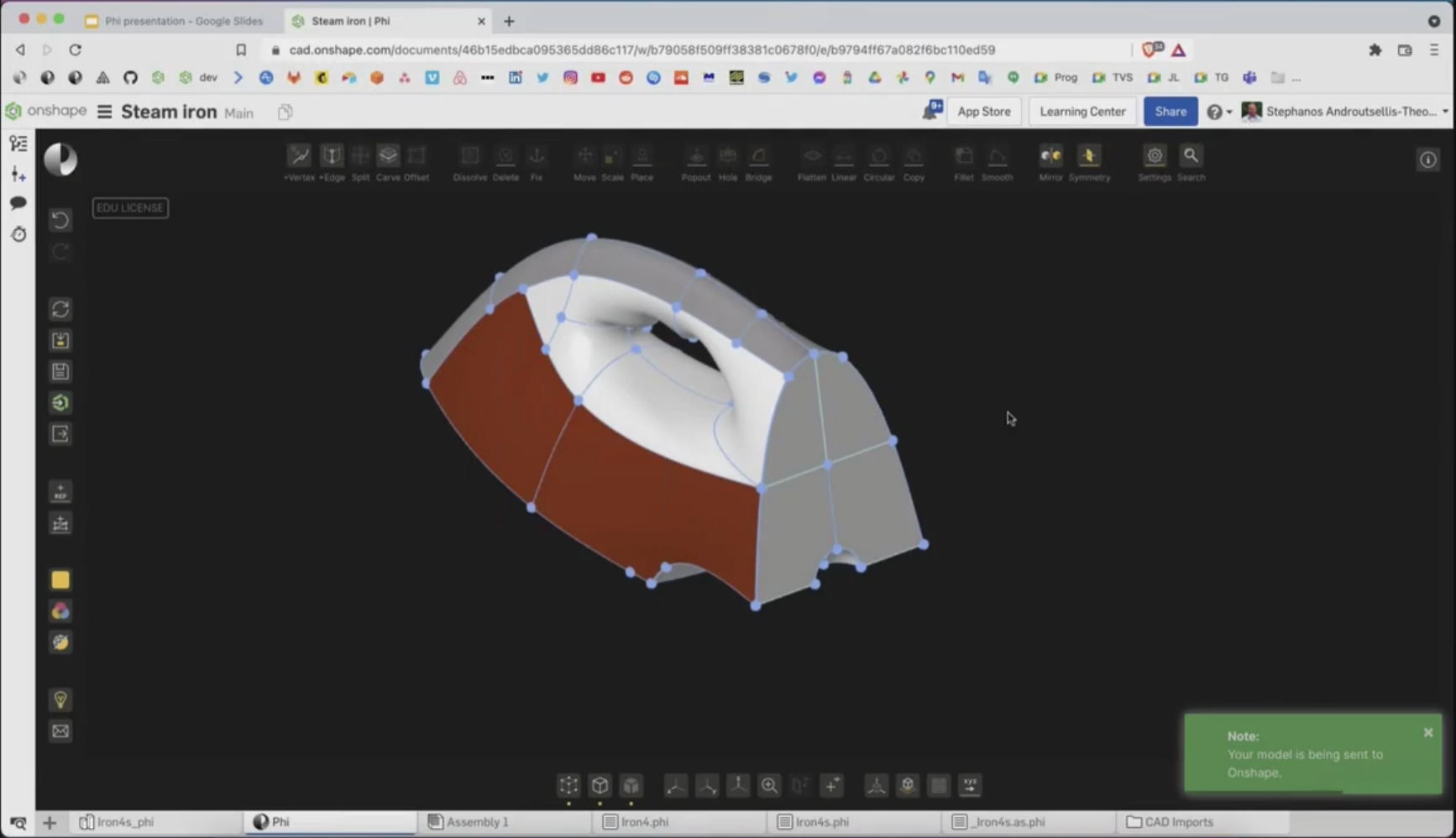

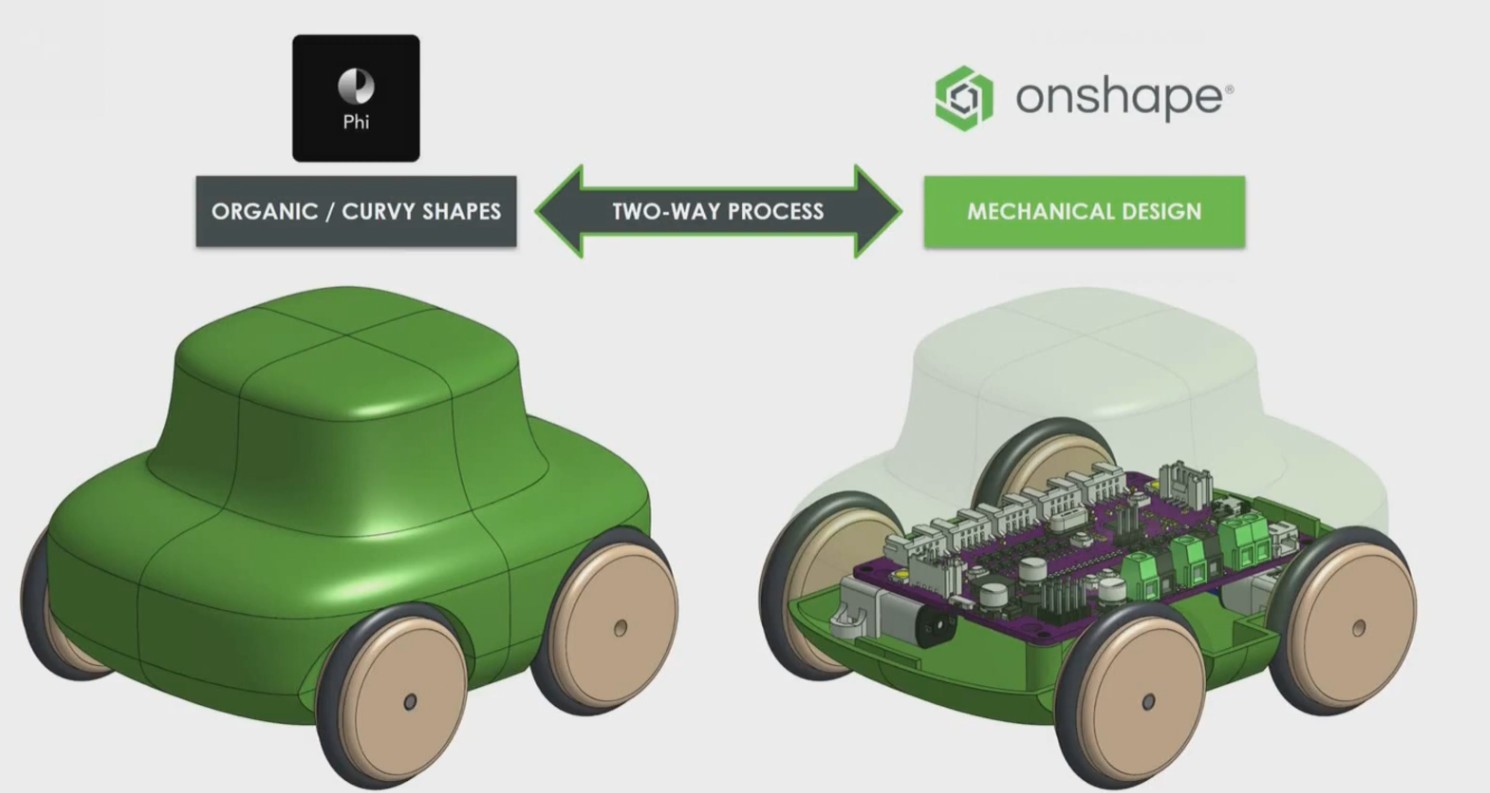

Phi is full-cloud software, like Onshape. However, rather than compete with Onshape, Phi works with Onshape. You can create your organic shape using Phi and finish it off in Onshape, which has additional tools such as Boolean operations (adding, subtracting, and intersection).

I have to wonder why Onshape does not use Phi as its shape engine, and then I remember: Onshape is beholden to Parasolid.

You can create a shape by pushing and pulling on a primitive shape (box, cylinder, etc.) from a library of shapes, or you can create a new shape. Edges define shapes. Phi uses n-sided patches, geometric entities that can have any number (n) edges, unlike subD modeling, which must have quad patches.

Modifying a shape is literally child’s play. The shape deforms naturally and exactly, unlike spline-based surfaces, which require trial and error to get a shape just so. The splines, not being part of the shape but only influencing them, require considerably more tweaking.

Too often fooled by demos in the hands of experts that make software look easy to use, I started a Phi account to create shapes myself. You can get a free trial (7 days) to try it out, but you have to supply a credit card. As it is full cloud, that’s all you need to do; there is no software to download.

It took only minutes to start making a part and modify a shape and confirm Phi’s ease of use. The demo had been no smoke and mirrors. Phi is indeed remarkably easy to use.

Granted, it will take more time to learn how to use Phi to make something useful and plenty of tutorials are available inside Phi for that purpose.

I find myself looking forward to learning how to use Phi — a feeling I have not had since the last big innovation in CAD (Shapr3D), which showed CAD being done with a pen/stylus interface. Like that, Phi is fun.