VIENNA, Austria and BRNO, Czech Republic, June 13, 2025 – The Institute of Physics of Materials of the Czech Academy of Sciences (IPM CAS) has purchased the first Lithoz CeraFab Multi 2M30 printer in the Czech Republic. Lithoz has completed the installation at the IPM CAS facilities, where the machine will support research within the MEBioSys project. This program, co-funded by the EU and the Czech Republic’s Ministry of Education, Youth and Sports (MEYS), focuses on developing hierarchical structures with sensory capabilities for use in biological and engineering applications like bone implants.

These three-dimensional structures support the development of medical solutions, including bone implants with embedded sensors. The devices incorporate piezoelectric sensors within the bioceramic structure, enabling monitoring of implants without additional invasive procedures. This allows the doctors to assess the implant performance and identify potential issues to provide patient-specific care.

A second research area involves smart adaptive aircraft wings designed to adjust vibration behavior. Electrical current is sent through conductive layers in coordination with the aircraft’s trajectory to modify wing stiffness and shift resonance away from frequencies that may affect turbine lifespan.

“As a result of our previous work, we recognized the need for a multi-material 3D printing solution to produce the complex structures required for our research,“ says Dr. Zdeněk Chlup, head of Brittle Fracture Group at IPM CAS. “The CeraFab Multi 2M30’s ability to print two materials in a single layer opens up a world of possibilities, especially in the integration of piezoelectric ceramics with metals and polymers. This technology will enable us to advance our research in ways we couldn’t before.”

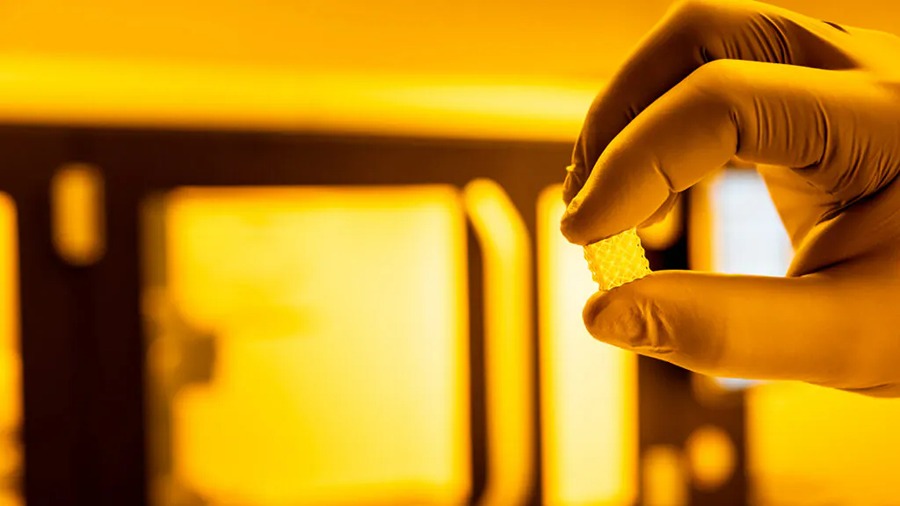

The Lithoz CeraFab Multi 3D printer can combine different materials, in here ceramic and metal, or two ceramics with separate features, into one functional part. It can mix different materials in a single print layer. With one print job, it can combine opposing properties or different levels of porosity, including both conductive and insulating sections. This process creates multi-functional parts with complex shapes.

The CeraFab Multi 2M30 supports the MEBioSys project’s R&D. After finishing test prints, the IPM team looks forward to using multi-material 3D printing to improve medical and engineering work.

Source: Lithoz

About Lithoz

Lithoz, founded in 2011 and headquartered in Vienna, Austria, specializes in developing and producing ceramic 3D printers and materials. The company serves various industries, including aerospace, automotive, jewelry, medical, and dental sectors. Lithoz’s proprietary Lithography-based Ceramic Manufacturing (LCM) technology enables the production of precise and reliable ceramic components suitable for applications ranging from casting-core to medical-grade bioceramics. As of 2025, Lithoz employs approximately 150 people. The company has secured grants and investments from the European Union and the EIC Fund. Lithoz’s commitment to quality is underscored by its ISO 9001:2015 certification, reflecting its dedication to continuous improvement and customer satisfaction.