Realize LIVE, the annual meeting for users of Siemens Software, was held recently at Huntington Place in Detroit. That is the most recent name for Cobo Hall, once a must-attend event for any and all in the CAD industry and those mechanical designers and engineers switching to MCAD from the drafting board. It was a time when Detroit was not a favored destination, but a city to be avoided. Most industry, including the big auto companies, had already fled to the environs. Detroit would get worse before it got better. This last time, I heard how it had had a resurgence, it was booming and there was new construction all over the place. Indeed, I see a construction crane from the 23rd floor of my hotel across from Huntington Place. But still, Detroit’s reputation precedes it. When I left for Detroit, I promised my wife I would check in with her on a regular basis.

Brenda Stars

Any annual user conference of a major CAD company is a burst of energy. The pressure builds for a year is released over several days. It is the one time a year when far-flung staffers see each other in person, sometimes for the first time, take talking points from their leaders and greet and meet VIPs, i.e., customers. Major CAD annual events are as much company and customer meetings as they are user meetings.

They are also somewhat of a draw for the industry press and analysts, though it seems as if their numbers are dwindling.

Asking attendees what they would like of AI, the hot topic of every conference for the last two years, was none other than the energetic, always-on Brenda Discher, SVP, Business Strategy & Marketing and Strategic Marketing & Communications for Siemens Digital Industries.

“They asked me if I wanted to interview people during the event. And since I had nothing to do…” jokes Brenda when we talk after the Executive Q&A.

Siemens Advantage: Software Plus Manufacturing

Realize LIVE is the smallest big CAD event, with 2500 attending this time in Detroit. The venue formerly known as Cobo Hall was once the site of Autofact, where design software met the auto industry. Most industry trade shows did not survive the Internet and we have today mostly annual user meetings.

Nevertheless, Realize LIVE is a tectonic movement. Here is one of the two largest CAD, CAM, and CAE software companies, with perhaps the most diverse product portfolio, part of an international manufacturing conglomerate (Siemens AG) that employs over 300,000 people.

Unlike the pure software makers, Siemens Digital Industries Software is unique in being part of a manufacturer, Siemens AG. This not only gives it a ready market for its software but a real-world test bed and an ongoing stream of valuable data from its products in actual use. It is data that AI can feast on and learn from. The other CAD companies have nothing like it. They may have customer data from their cloud applications but cannot use it to train AI since that would compromise each customer’s IP.

Siemens AG, on the other hands has training data galore — 150 petabytes by their estimation — from all their manufacturing operations, factories, PLCs, trains, energy utilities, power generation stations, wind turbines… and more.

From this will come AI agents that can assist you, the engineer, in your job. Siemens announced a slew of such agents recently and promises more are on the way.

Welcome to Detroit

Siemens Digital Industries Software President and CEO Tony Hemmelgarn opened the event with a welcome to his hometown, Detroit[i]. We’ll refer to Tony by his first name. Everybody else does. Tony starts by invoking Heraclitus, “No man steps in the same river twice, for it is not the same river and he is not the same man.” There’s no better way to say that digital representations, from geometry models of assemblies to full digital twins of machines and systems, are time-dependent.

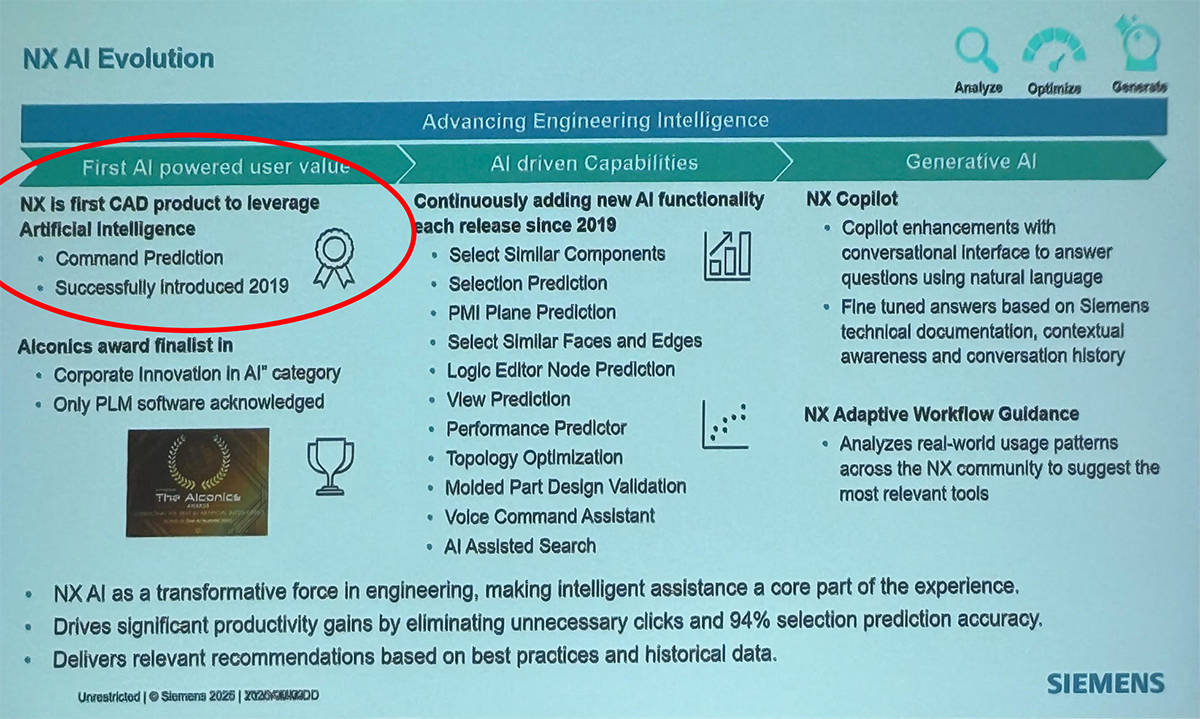

AI is to be a big part of Tony’s keynote. We’ve certainly become accustomed to hearing from CAD companies reacting to the AI phenomenon and claiming they’ve had AI all along, as long ago as 20 years, in fact. This is usually the result of retroactively labelling AI the few smarter-than-humans (their words) technologies, like topology optimization, they had developed. At Realize LIVE, Siemens makes a far more sensible claim (during a session on NX), saying it was first to implement AI, using today’s definition of AI[ii], when they introduced command prediction, the precursor to Copilot, in 2019.

Siemens is embedding AI-driven capabilities across its Xcelerator portfolio, boldly going where no CAD or CAE has gone before, to automate problem detection, optimize workflows, and streamline engineering and manufacturing processes. And I, impatient for AI to be finally put “computer-aided” into CAD, am eating it up.

Examples of AI included:

- Using AI in Teamcenter to automate issue detection.

- Applying AI in the Simcenter suite to cut engineering simulation times.

- Leveraging AI in manufacturing software to synchronize factory operations and handle configuration challenges.

Tony emphasized that Siemens views AI not as a “sudden breakthrough,” but as the result of years of investment in software and data management. He made a parallel to planting a bamboo and seeing no growth for 4 years. Then in the 5th year, the bamboo pops out of the ground in 6 weeks, is 90 feet tall. You see, for 4 years, the bamboo had been developing a root system, explains Tony.

“We tend to overestimate the effect of technology in the short term and underestimate the effect in the short term,” says Tony.

Altair Acquisition Expands Siemens’ Simulation Reach

Tony extolled the recently completed acquisition of Altair, calling it a strategic move to enhance Siemens’ simulation and digital twin capabilities. Altair’s software brings more advanced non-linear computing, structural analysis, thermal analysis, circuit analysis, and more, to the mix. Indeed, it adds much to Siemens’ vast product portfolio, particularly in AI applications in simulation and data analysis (RapidMiner). Altair strengthens and adds to what Mentor brough to Siemens, allowing Tony to say that Siemens “goes from the chip to the grid[iii].”

Integrating Altair technologies is intended to strengthen Siemens’ position in simulation-driven design and enable more sophisticated modeling and predictive capabilities across industries.

Workhorse Speeds EV Development with Siemens Xcelerator

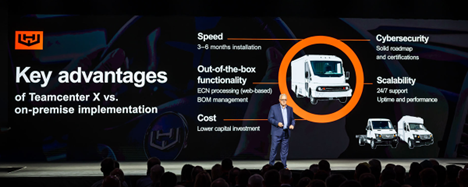

One of the day’s customer highlights came from Workhorse Group, a U.S.-based maker of zero-emission commercial vehicles. Jeff Mowry, Workhorse CIO, described how the company adopted Siemens Xcelerator, including NX and Teamcenter X, to overhaul its design and production processes.

Without a dedicated internal IT team, Workhorse was able to quickly deploy its new PLM infrastructure. According to Mowry, the move reduced costs, enhanced cybersecurity, and provided the company with the flexibility needed to support its expanding electric vehicle lineup. Workhorse developed its latest Class 5 electric truck from design to production in 22 months—a compressed cycle that Mowry credited in part to Siemens’ tools.

_______________________

[i] Tony Hemmelgarn was born and raised in Ohio, according to Siemens’ website, moving to Detroit in 1996, according to his LinkedIn profile.

[ii] AI is that which replaces if-then programming with neural networks and machine learning.

[iii] The grid, in this case, is a data center. Siemens software can indeed go from designing and analyzing the semiconductor itself to the datacenter in which millions of semiconductors are housed.