HANOVER, MD and LINARES, Spain, June 6, 2025 – Phillips Corporation and Meltio have announced the integration of the Meltio Engine Blue into a Haas CNC machine, making Phillips the first partner globally to achieve this configuration. The integration combines additive and subtractive manufacturing technologies within a single machine setup, streamlining hybrid workflows. This development is intended to support advanced and flexible manufacturing applications within the defense sector.

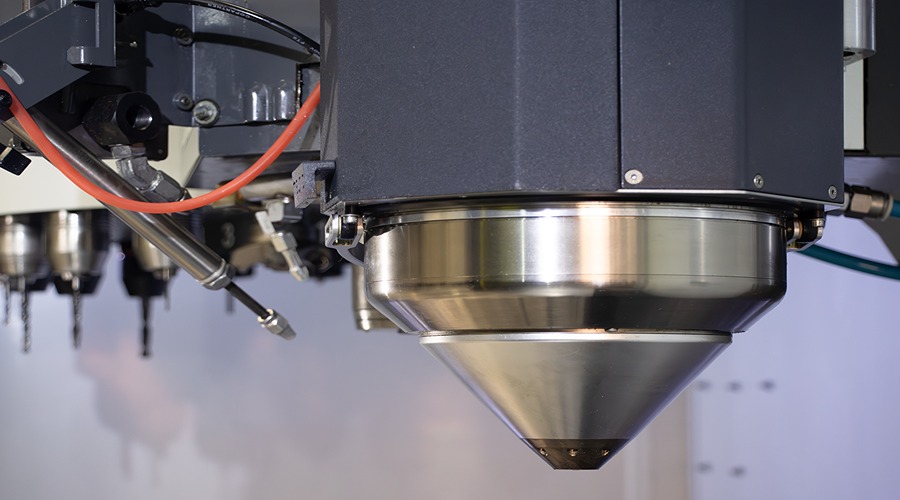

Meltio’s laser-wire metal 3D printing system uses welding wire as its feedstock, proposing a practical and available material option. The Meltio Engine Blue empowers defense and industrial manufacturers to extend CNC machining capabilities by incorporating metal additive processes, supporting the production of functional components within existing workflows.

The first Meltio Engine Blue was integrated into a Haas TM-1r, a CNC platform recognized for its precision and reliability, and showcased at RAPID TCT in Detroit, MI, this past April 2025. This hybrid configuration enables defense manufacturers to produce complex metal parts with precision, shorter lead times, and reduced material waste – capabilities essential for logistics, sustainment, and deployment environments. This milestone builds upon previous defense collaborations between Phillips and Meltio, including the deployment of Meltio technology aboard a U.S. Navy ship for onboard metal part manufacturing and the U.S. Department of Defense’s adoption of Meltio’s wire-laser metal 3D printing systems to increase supply chain resilience. These developments highlight the role of hybrid manufacturing in supporting modern defense manufacturing requirements.

To share this achievement and demonstrate its full potential for defense applications, Meltio and Phillips Corporation will host a live webinar on June 11, 2025 at 17:00 CET (11:00 AM EDT). The event will introduce the “Meltio Engine Blue”, explain its integration with Haas CNC machines by Phillips, and highlight how this hybrid solution improves efficiency, precision, and flexibility. The session will feature a live system demonstration followed by a Q&A with technical experts from both companies.

“Integrating Meltio’s impressive new Engine Blue into the Haas CNC platform unlocks a new level of control and versatility for manufacturers,” said Brian Kristaponis, general manager of Phillips Additive Hybrid. “We’re proud to be the first Meltio partner to deliver this configuration through our Hybrid product line, which is already proving its value in fast-moving, resource-constrained environments like defense.”

Meltio marks this integration with Phillips Corporation as a step toward expanding the use of metal additive manufacturing in defense and other industrial applications.

As Meltio channel manager in the United States, Gabriel Ortiz, expresses enthusiasm for this partnership: “The demand for manufacturing increasingly complex 3D printed parts with Meltio’s DED metal technology using a CNC machine is increasing in different industries in the United States. As our long-standing partnership with Phillips Corporation in the United States demonstrates, the integration of Meltio into Haas CNC certifies that we continue to keep pace with this growing industrial demand for DED metal parts. Meltio’s laser-wire metal 3D printing solutions offer all types of industries in North America the ability to manage the entire manufacturing process using Hybrid solutions like those offered by Phillips Corporation It is extremely rewarding to help a large range of industries, from automotive to aerospace, as they aim to print and repair reliable metal parts with our reliable laser-wire DED solutions.”

Source: Meltio

About Phillips Corp.

Phillips Corp., established in 1961 and headquartered in Hanover, MD, is a privately held company specializing in manufacturing solutions. The company offers a range of services, including CNC machine tools, additive manufacturing, machine tool service, manufacturing applications engineering, robotics, training, and education. With a global presence, Phillips Corporation serves various industries such as aerospace, defense, energy, and education. It operates through multiple divisions, including the Commercial Division in the United States and Phillips Machine Tools in India. As of 2025, the company employs approximately 375 individuals worldwide and reports an estimated annual revenue of $75 million. Phillips Corporation has maintained a longstanding partnership with Haas Automation, serving as a Haas Factory Outlet for over 30 years. The company’s commitment to innovation is evident in its collaborations with technology leaders and its involvement in public-private partnerships, including initiatives with the U.S. Department of Defense to advance additive manufacturing capabilities.

About Meltio

Meltio, founded in 2019 and headquartered in Linares, Spain, specializes in metal additive manufacturing solutions using its proprietary wire-laser Directed Energy Deposition (DED) technology. The company offers a range of products, including the Meltio M450 and M600 3D printers, as well as integration kits for CNC machines and robotic systems, enabling hybrid manufacturing capabilities. Meltio serves various industries such as aerospace, defense, automotive, energy, and education, providing tools for both production and research applications. As of early 2025, Meltio has sold over 500 systems worldwide, with installations in more than 60 countries, and employs approximately 120 people. In 2024, the company reported a 50% increase in revenue compared to the previous year, reflecting its growing market presence. Notably, Meltio’s technology has been adopted by several defense organizations, including the U.S. Navy, the French Navy, and the South Korean Army, for on-site manufacturing and repair of metal components.