BOSTON, MA and DETROIT, MI, May 14, 2025 – At Automate 2025, Realtime Robotics introduced Resolver, a cloud-based solution designed to streamline the development of robotic workcells.

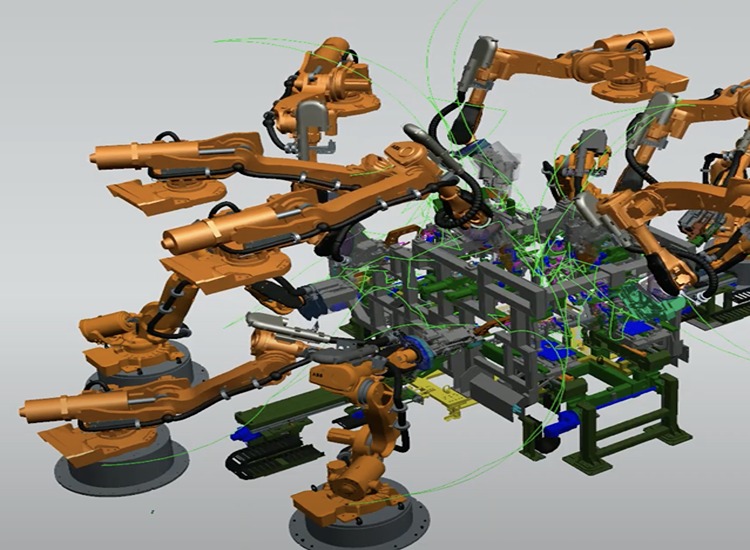

In manufacturing environments, coordinating the motion of multiple robots requires manual effort – engineers define collision zones, interlock signals, and path sequences to prevent interference and meet cycle time goals. This process is not only labor-intensive but also prone to inefficiencies. For a single project, teams can spend over 100,000 hours on path planning, mechanical design, and sequencing. Despite the investment, around 10–15% of workcells still require rework due to missed cycle time targets or design flaws. Resolver automates key workflow steps, reducing time and risk in multi-robot system deployment.

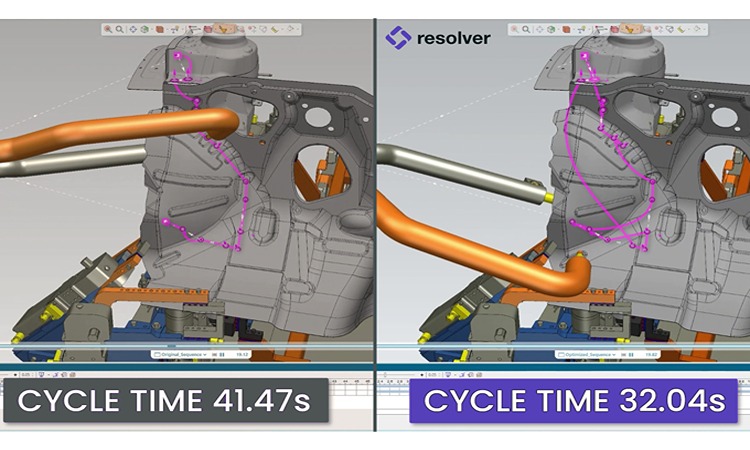

Realtime Robotics’ Resolver selects and tests potential solutions faster than a human programmer. It generates motion paths and interlock signals that avoid collisions. With Resolver, organizations can find the fastest target order, reducing workcell design time from months to days. This also decreases engineering effort by 50%. Workcell cycle times decrease, and overall throughput rises.

Resolver gives users affordable, on-demand, scalable robotic simulation power that can be used to speed the process of:

- Generating accurate proposals

- Designing optimal tools and fixtures that support cycle time goals

- Producing optimal robot programs

- Adjusting for as-built deviations during commissioning

- Assessing and minimizing the impact of product design changes in the manufacturing phase

“It is widely understood that the future of the manufacturing industry lies in robotics and automation. However, that future is slow to materialize because of the outdated, time-consuming, and inefficient processes commonplace in the industry,” said Peter Howard, CEO of Realtime Robotics. “Few manufacturers have the time or resources needed to enact real change. We’ve engineered Resolver to help manufacturers improve their engineering, programming and production processes – and drive greater value from their current and future investments in robots.”

How Resolver Works

Realtime Robotics’ Resolver is designed to support path planning for multiple robots at any stage of the development process, delivering results within minutes. The tool requires minimal setup and currently integrates with Siemens Process Simulate, allowing users to work within their existing environment. Integration with additional simulation platforms is planned for later this year, expanding compatibility with industry-standard tools.

“Resolver has the computational power to generate better motion paths than human programmers in both simple and complex workcells,” added Howard. “This is because Resolver searches the possibilities open to robotic arms, while humans tend to stay within the possibilities of the human arm.”

Organizations upload the workcell information into a new project, set their sequencing and conditions, and execute a run. Within minutes, Resolver generates motion paths, including interlocks, to reduce cycle time. The longer Resolver runs, the more options it provides, shortening the cycle time until the desired result is achieved. The paths and interlocks can then be imported back into the simulation software for validation and operation.

“Resolver eliminates the most time-consuming aspects of industrial robotics – the programming and optimization of the robots. What used to take months to accomplish can now be measured in hours,” added Marco Bizjak, head of competence center digital factory and technical manager, digitalization, at FFT. “We believe this can be a real competitive advantage as we strive to help our customers establish the most efficient and effective manufacturing processes possible.”

Additional Uses

Resolver includes features that make it usable throughout the project lifecycle, from proposals to workcell designs. By generating collision-free motion paths and providing cycle time estimates early in the process, it helps teams develop competitive bids. During the design phase, it reduces manual path planning to a sequence, defining interlock signals, and limits the need for repeated mechanical design changes.

In addition to motion planning and interlock generation, Resolver supports fixture design, reachability analysis, target sequencing, and robot task allocation. It can also be applied in the development of an entire manufacturing line, allowing teams to design coordinated paths and interlocks across all robots from the outset. This early-stage planning supports system-level optimization and allows engineers to focus on critical tasks later in the project.

Upcoming Events

Realtime Robotics will showcase its Resolver solution at two upcoming industry events. At Automate 2025, held from May 12–15 in Detroit, MI. They will also exhibit at Automatica 2025 from June 24–27 in Munich, Germany. Visitors can see Resolver in action and learn how it supports engineering and manufacturing workflows.

Source: Realtime Robotics

About Realtime Robotics

Realtime Robotics, founded in 2016 and headquartered in Boston, MA, specializes in collision-free motion planning and optimization software for industrial robots. Its flagship products, RapidPlan and Resolver, enable manufacturers to automate robot programming, simulate workcells, and optimize multi-robot coordination, significantly reducing cycle times and improving throughput. The company’s solutions are utilized across various industries, including automotive, logistics, and electronics manufacturing, to enhance productivity and operational efficiency. As of 2025, Realtime Robotics has raised approximately $100 million in funding and employs around 60 people. Its estimated annual revenue ranges between $15 million and $21 million. The company also operates in Berlin and Tokyo, expanding its reach and supporting global clients with advanced robotic automation solutions.