Throughout human history, physical deformities have been a source of both emotional and physical hardship. During the worst of times, between 1939 and 1945, a visible deformity could have you killed. Nazi Germany’s euthanasia program, which targeted disabled people—including those with visible deformities—is estimated to have killed 275,000 people through starvation, lethal injection, or gas chambers. As recently as the last century in America, children with deformities were kidnapped or sold to circuses and displayed as long as they lived as curiosities or monsters.

By comparison, a sunken chest may not seem so bad. But don’t tell that to a teenage boy born with pectus excavatum, commonly referred to as funnel chest. Body image is all-important during adolescence, and not looking like other boys can be devastating. There is nothing they can do besides keep their shirt on. The chest can be operated on, the breastbone reconstructed, for the severe cases when it affects the heart, lungs or esophagus. But for cosmetic cases, surgeons will not operate on minors, leaving teens affected by funnel chest in anguish for their entire adolescence.

But at least one company offers them the hope that one day, though not soon enough, it will be over.

Enter AnatomikModeling

Funnel chest results in a sunken appearance of the chest due to abnormal growth of cartilage connecting the ribs to the sternum (breastbone). It affects up to 1 in every 300 births, and three to five times more often in males. It’s as if Someone decided females bore all the burden of chest problems and wanted males to have one of their own.

While severe forms can impair cardiopulmonary function, most cases are milder. Despite its visibility and prevalence, effective, individualized, and less invasive surgery—surgery that does not require cutting bone—has remained elusive until now.

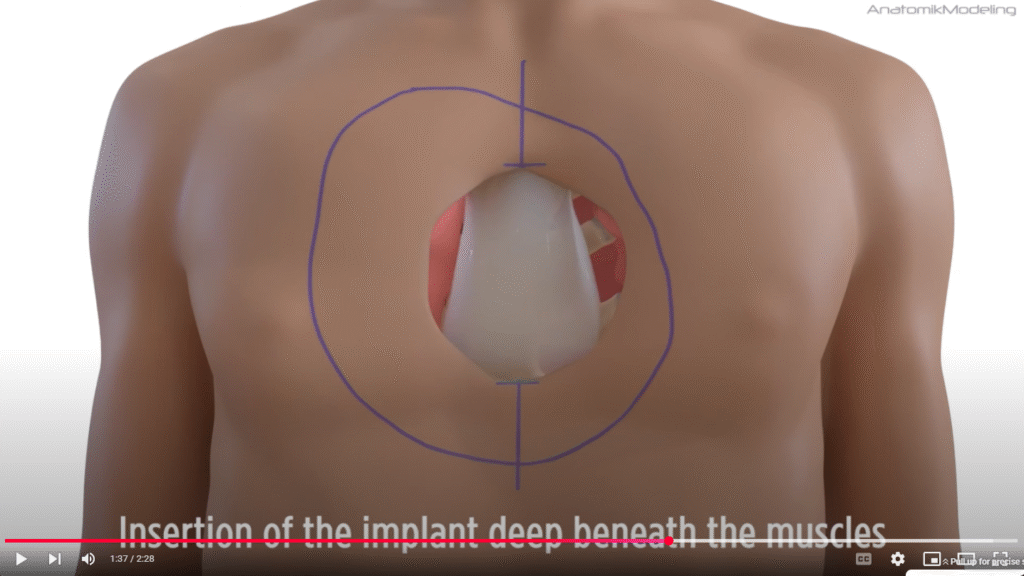

One way to mitigate the appearance of funnel chest is with a surgical implant. Silicon implants, commonly used for female breast augmentation, are useless here because the sunken sternum presents an irregularly shaped cavity to be filled, instead of a rounded shape to be added.

The development of a new surgical prosthetic that will fill the chest cavity is being propelled by advances in medical imaging, digital modeling and AI, by Benjamin Moreno, who founded the French firm, AnatomikModeling at the improbable intersection of neuroscience, archeology, and reconstructive surgery. Moreno is a researcher whose early work focused on mapping the neural connections of honeybees using advanced imaging techniques. This background in visualization, coupled with a serendipitous collaboration with both an Egyptologist and a plastic surgeon, would eventually lead him to address funnel chest.

The journey began with CT-scanning—an imaging method traditionally used to observe the internal structure of patients for diagnosis or surgery planning. Moreno had originally applied CT-scanning to mummies so they could be visualized inside their sarcophagi but may with so few mummies and so many untreated funnel-chested boys, he might have realized where his skills could be more useful. He discovered the same tools could be employed to study living anatomy with unprecedented detail. When he crossed paths with Professor Jean-Pierre Chavoin, then head of plastic and reconstructive surgery at Toulouse University Hospital, the potential for applying his imaging expertise to medicine became clear.

Prof. Chavoin had been designing chest implants manually using plaster molds. The procedure was catching on and he could not get the molds made fast enough. Plus, the technique was imprecise since the mold was made from the external contours of the chest. Together, the two reimagined the process using CT scan data to create customized, patient-specific implants that addressed the precise internal anatomy of the patient.

The new workflow introduced by Moreno and Chavoin incorporated high-resolution imaging, 3D modeling software, and rapid manufacturing technologies. CT scans offered detailed anatomical data, which could be segmented and digitally reconstructed to form a “digital twin” of the patient’s torso. These models enabled the design of silicone implants tailored precisely to each patient’s unique anatomy. Instead of relying on general-purpose implants, surgeons could now insert biocompatible, polymerized silicone prosthetics beneath the skin.

The new approach was accelerated with AI. In 2024, AnatomikModeling partnered with the software company Volume Graphics (part of Hexagon) to beta-test the new VGTRAINER application.

“With VGTRAINER, we found we could automate all our segmentation steps,” says Moreno. “It’s extremely efficient and robust in terms of segmentation quality.”

By training AI models on thousands of anonymized and accurately segmented cases, Moreno’s team created a system capable of automatically identifying and isolating muscles, bones, fat, and cartilage. This speed has not only reduced implant design time but also enabled the company to scale its operations, able to produce up to 40 implants per month.

“When we began Beta testing, we started with 20 existing and accurately segmented patient data sets, fed them into VGTRAINER, ran it for about 36 hours, and ended up with a model that could segment subsequent datasets at about 98 per cent accuracy in just 15 to 20 seconds,” says Moreno. “We’re saving half an hour per patient case.”

Still, each implant is developed in partnership with the operating surgeon, ensuring both medical appropriateness and optimal fit. The final designs are manufactured under ISO 13485:2016 standards and must undergo rigorous validation, including visual review by experienced engineers and doctors. Patients report higher satisfaction, better cosmetic outcomes, and restored confidence, according to a 20-year longitudinal review comparing plaster-mold and CT-based designs.

Although funnel chest correction currently comprises the bulk of AnatomikModeling’s work, the foundational technologies and AI models they have developed are being adapted for other surgical applications, including facial reconstruction, muscle atrophy correction, and even airway stents. The implications are profound: as digital modeling and deep learning become more accurate and accessible, the possibility of personalized implants for a wide array of deformities becomes not just possible, but scalable.