PLANO, TX, Jan 29, 2025 – Siemens Digital Industries Software announced the latest update to its Simcenter portfolio, delivering advancements in aerostructure analysis, electric motor design, gear optimization, and smart virtual sensing. The enhancements are designed to streamline workflows, accelerate certification, and provide deeper insights into system performance.

“These updates empower engineers to meet the evolving challenges of electrification and advanced air mobility,” said Jean-Claude Ercolanelli, senior vice president, simulation and test solutions, Siemens Digital Industries Software. “We’re delivering tools that drive innovation, improve efficiency and support a more sustainable and connected future. Our Simcenter portfolio is transforming engineering simulation.”

Key updates and benefits:

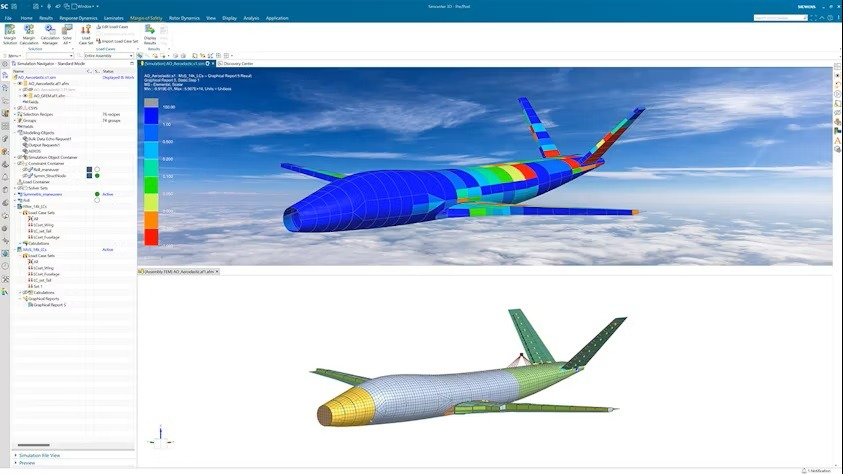

Integrated Aerostructure Analysis: Simcenter automates the creation of free-body diagrams and margin of safety (MoS) calculations, accelerating certification schedules by 20 percent. Engineers can now evaluate load paths across aircraft models and perform full-envelope MoS analysis without the need for costly in-house tools.

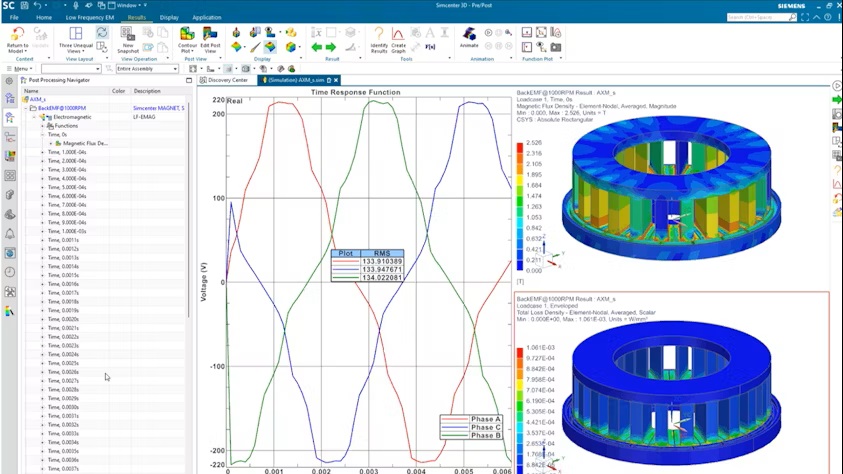

Axial flux motor simulation: Simcenter enables faster design and simulation of compact, high-power-density motors. Engineers can quickly create lightweight designs using Siemens’ Simcenter E-Machine design software, then transition seamlessly to 3D simulations in Siemens’ Simcenter 3D software for comprehensive electromagnetic, thermal and mechanical performance assessments.

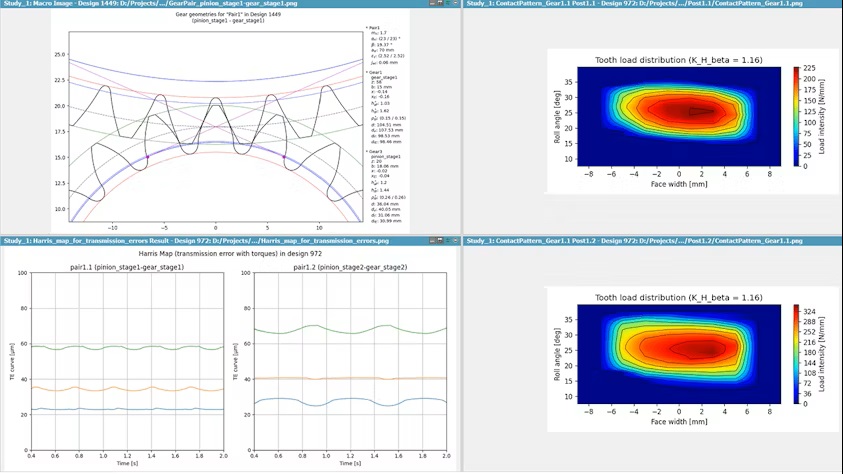

Gear Design Optimization: Simcenter introduces lightweight gear blank parameterization and an optimization framework to improve gearbox noise, vibration and harshness (NVH) performance. These tools help reduce late-stage design changes and streamline the development cycle.

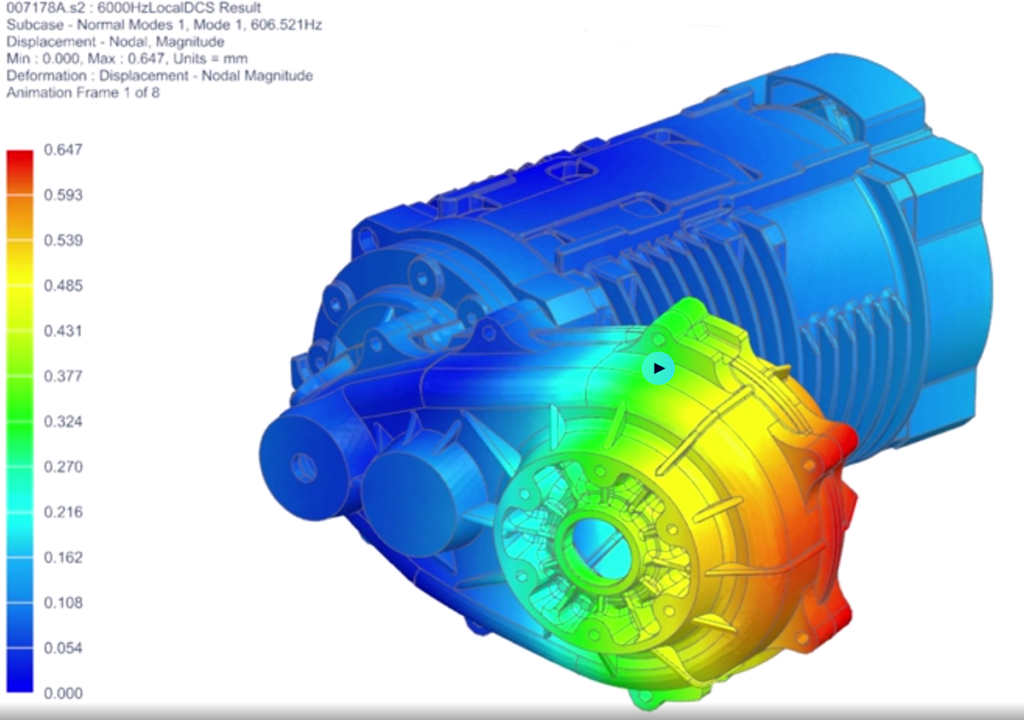

Extended Smart Virtual Sensing: Simcenter expands capabilities to include rigid body motion sensors and damage assessment tools, providing insights into the durability and remaining useful life of machines even in challenging test environments.

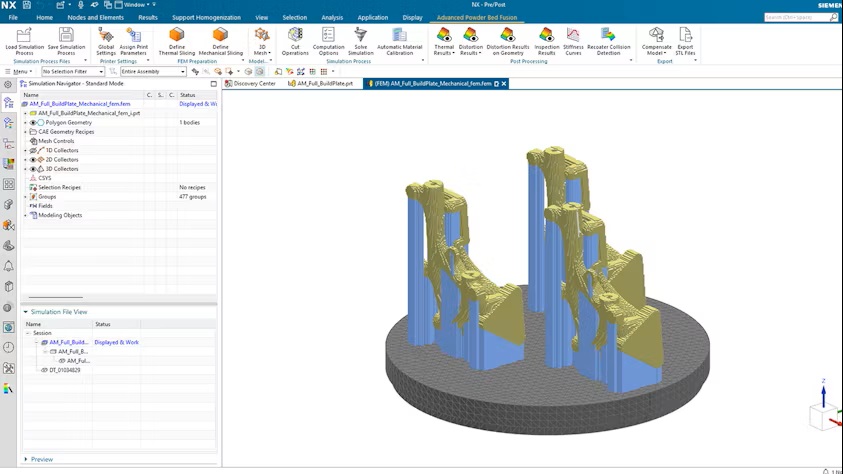

Simulation efficiency and collaboration: Speeds up additive manufacturing simulations by a factor 200 percent with voxel mesh improvements and enhances collaboration with centralized model data and streamlined load and boundary condition transfers.

About Siemens Digital Industries Software

Siemens Digital Industries Software provides comprehensive solutions for digital transformation, offering software and services that enable companies to improve product design, manufacturing, and operational processes. It serves a wide range of industries including automotive, aerospace, industrial machinery, electronics, and consumer products. Siemens Digital Industries Software has contributed towards innovation in manufacturing and product lifecycle management (PLM). The company is headquartered in Plano, TX, and is part of Siemens AG.

Source: Siemens