PLANO, TX, May 29, 2025 – Siemens Digital Industries Software has announced that it is extending access to its AI-driven electronic systems design tools by offering PADS Pro Essentials and Xpedition Standard software to small and mid-sized businesses (SMB). The aim is to make design tools accessible to engineering teams with limited resources.

Built on Siemens’ Xpedition technology, the new offerings combine intuitive user experiences, integrated cloud collaboration and AI-driven automation to empower small teams and independent engineers with the same professional-grade tools used in complex electronics, at lower cost.

“Today’s launch marks a major milestone in our strategy to democratize access to high-performance PCB design and bring the transformative power of AI to the PCB design workflow,” said AJ Incorvaia, senior vice president, Siemens EDA. “With PADS Pro Essentials and Xpedition Standard, we’re delivering scalable solutions that help smaller teams move faster, work smarter, and design with confidence without sacrificing quality or budget.”

PADS Pro Essentials delivers a streamlined, cloud-connected design environment built on Siemens’ proven Xpedition technology at an entry-level price. Tailored for independent engineers and startups, it includes schematic capture, layout, and a design experience that lowers barriers to professional-grade PCB design tools. The Essentials tier also introduces an integrated, co-branded front-end powered by CELUS, allowing engineers to use AI-assisted workflows and design with functional blocks, streamlining both schematic creation and BOM generation. This reduces manual steps and improves design consistency.

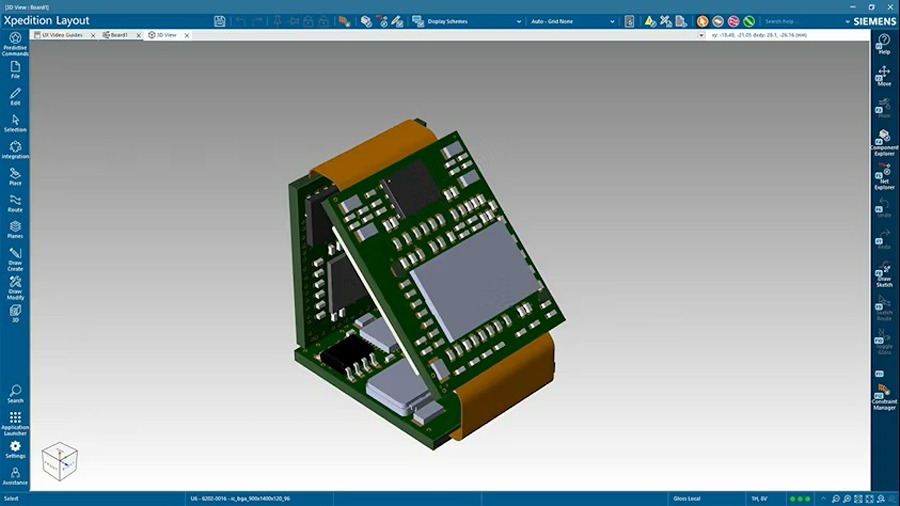

Xpedition Standard is designed for engineering teams balancing capability and cost. It includes tools for design reuse, variant management, automated routing, and native 3D layout, enabling collaboration across mechanical, manufacturing, and supply chain processes. The software supports modular expansion through token-based access to capabilities such as signal integrity analysis using Siemens’ HyperLynx and tools for rigid-flex PCB design. This structure lets teams add features without full-tier upgrades, supporting flexible PCB workflows.

“We took a close look at Xpedition Standard and were genuinely impressed,” said Shrouk El-Attar, founder, Shrouk El-Attar consultancy. “Siemens has clearly reimagined the experience. It’s intuitive, modern, and far more connected and integrated than we expected. From day one, it felt like a tool built for the way we actually work. I can get real design work done without fighting the software.”

Source: Siemens

About Siemens Digital Industries Software

Siemens Digital Industries Software delivers integrated tools and services to support digital transformation across engineering and manufacturing workflows. Its offerings help companies streamline product design, optimize manufacturing, and manage operational data more effectively. The company serves sectors such as automotive, aerospace, industrial equipment, electronics, and consumer goods. Its work in areas like product lifecycle management (PLM) and manufacturing systems plays a key role in advancing digital continuity and efficiency. Headquartered in Plano, Texas, it operates as a business unit of Siemens AG.