NUREMBERG, Germany, June 3, 2025 – Siemens is collaborating with Hirano Tecseed, a Japanese machine builder, to improve battery production systems. The partnership aims to standardize and digitize battery coating machinery, making the coating process consistent and measurable. This approach is intended to reduce material waste, improve product quality, and support stable operator workflows. By applying automation and digital tools to these systems, the companies aim to support a consistent production processes, with a focus on lithium-ion battery manufacturing.

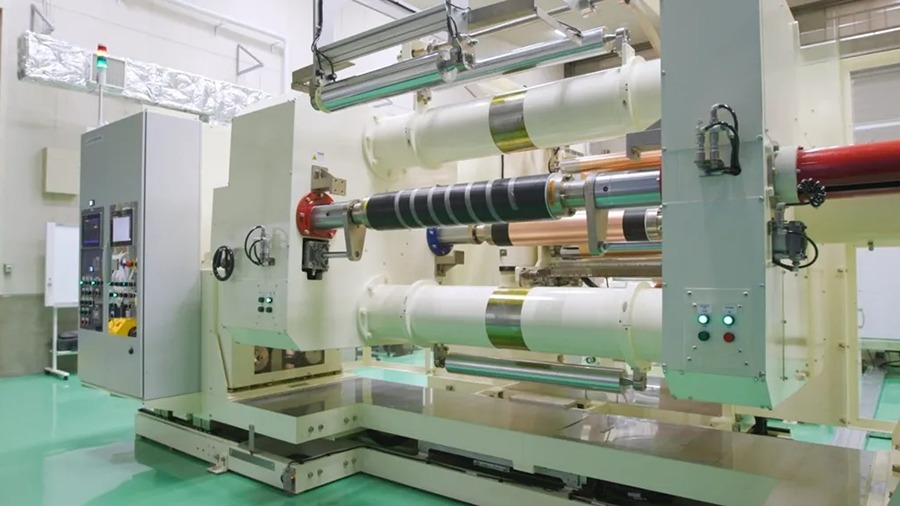

The battery industry is growing on an upward trend, driven by demand for electric vehicles and utility-scale energy storage systems. To meet this demand, equipment manufacturers like Hirano are focused on improving production efficiency while managing cost, quality, and safety requirements. One significant step in battery manufacturing is the coating of foil strips with multiple active material layers to form battery electrodes. Defects in this stage can compromise battery performance and lifespan. Managing web speed and tension during coating helps maintain quality and process control.

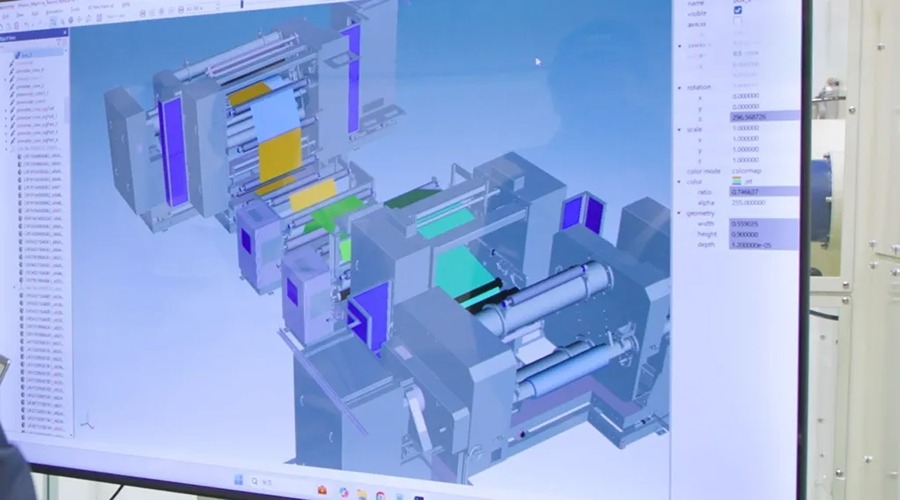

A key component of the collaboration has been the development of digital twin for battery manufacturing equipment. Using Siemens’ Simcenter software, Hirano simulated and tested a digital twin of its battery coating machine. Drawing on real-time data from a Simatic controller and Sinamics drives, which automate the pilot machine, the simulation provides accurate virtual model for performance testing. By leveraging Simcenter Amesim, a systems simulation software from the Siemens Xcelerator platform, Hirano’s design engineers can virtually assess and optimize the machine’s web handling system for maximum throughput.

In the past, Hirano relied on operator experience to set machine parameters, which sometimes resulted in incorrect settings and product defects. With Siemens’ digital twin technology, Hirano can configure and simulate machines virtually before building them. This approach reduces reliance on physical prototypes and improves the ability to identify potential defects early. Development engineers can test and adjust machine settings in the virtual model up to five times quicker than with physical equipment. Additionally, about 80 percent of the simulation and digital twin can be built using standardized function blocks, which shortens implementation and commissioning timelines and helps reduce overall development costs.

“We’re thrilled to collaborate with Siemens to enhance our battery manufacturing processes,” said Katsuhiro Omori, director and executive officer of R&D at Hirano Tecseed. “Integrating mechatronics and automation simulation systems into a unified modeling environment has significantly helped Hirano identify potential product defects and advance our machine process optimization in a virtual setting.”

“By leveraging our advanced simulation and automation technologies, Siemens is enabling Hirano to achieve unprecedented levels of efficiency and quality in battery manufacturing,” added Michael Thomas, senior vice president of factory automation and head of production machines at Siemens. “This partnership exemplifies our commitment to driving innovation and supporting our customers in their digital transformation journey.”

Source: Siemens

About Siemens Digital Industries (DI)

Siemens Digital Industries (DI), a division of Siemens AG, focuses on industrial automation and digitalization. Based in Nuremberg, Germany, the division provides software, automation systems, and digital services that support the full product and production lifecycle—from design and engineering to manufacturing and maintenance. With a history extending over six decades, Siemens DI serves key sectors including automotive, aerospace, pharmaceuticals, energy, and electronics. Its technologies, such as the Xcelerator platform and SIMATIC automation systems, are designed to integrate physical and digital processes, enabling data-driven manufacturing and operational efficiency. The division reports annual revenues exceeding €18 billion and employs approximately 70,000 people globally. Its portfolio supports manufacturers in implementing Industry 4.0 strategies by linking simulation, automation, and real-time data in scalable systems.

About Siemens AG

Siemens AG, based in Munich, Germany, is a global technology company with operations across industry, infrastructure, transportation, and healthcare. Founded in 1847, the company provides a broad range of products and services, including industrial automation systems, digitalization tools, energy-efficient technologies, and medical diagnostic equipment. In fiscal year 2024, ending September 30, Siemens reported revenue of €75.9 billion and net income of €9.0 billion. The company employs more than 312,000 people worldwide, with around 90,000 in Germany. Siemens is one of Europe’s largest industrial manufacturers and plays a key role in global markets for automation and industrial software.

About Hirano Tecseed

Hirano Tecseed Co., Ltd., founded in 1935, designs and manufactures precision coating and drying equipment used across electronics, medical, and energy sectors. Its systems support production processes for items such as adhesive films, lithium-ion batteries, and display materials. The company offers a range of equipment, including die coaters, gravure coaters, roll coaters, and integrated drying systems. As of March 2024, Hirano Tecseed employs 420 people and reported annual revenue of approx. $326 million. The company has expanded its international operations, establishing a U.S. office in Norcross, GA, to serve the North American market. In addition to geographic expansion, Hirano Tecseed is working with Siemens to integrate digital twin technologies into its battery equipment portfolio, with a focus on process standardization and improved operational efficiency through digital transformation.