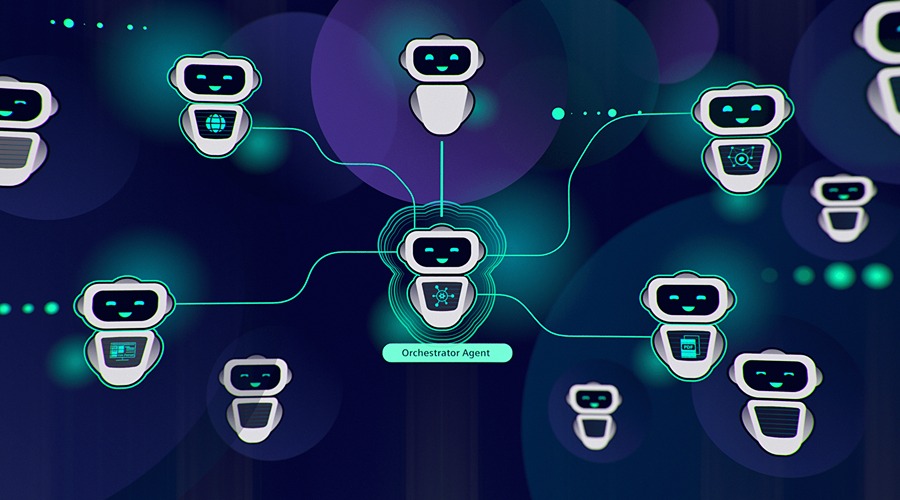

NUREMBERG, Germany and DETROIT, MI, May 13, 2025 – At Automate 2025 in Detroit, Siemens unveiled new advancements in industrial AI, introducing autonomous AI agents within its Industrial Copilot platform. Unlike traditional AI assistants that respond to user prompts, these agents are capable of executing manufacturing processes with minimal human supervision. The architecture includes a centralized AI orchestrator that assigns task-specific agents across the industrial automation value chain. These agents are designed to interpret user intent, learning from real-time data, and interface with external systems or other agents. While the system prioritizes autonomous decision-making, it allows users to retain operational control, determining which production or maintenance tasks to delegate. This shift signals a trend in smart manufacturing toward a scalable, self-directed automation.

“With our Industrial AI agents, we’re moving beyond the question-answer paradigm to create systems that can independently execute complete industrial workflows,” said Rainer Brehm, CEO factory automation at Siemens Digital Industries. “By automating automation itself, we envision productivity increases of up to 50% for our customers – fundamentally changing what’s possible in industrial operations.”

Automating automation: how the AI agent architecture works

Siemens distinguishes between Copilots as interfaces and backend AI agents. The company is developing digital agents and incorporating physical components, such as mobile robots. These elements form a multi-agent system where software and hardware agents operate in coordination. A core aspect of Siemens’ approach is the orchestration framework that manages these agents within an ecosystem. This framework supports both Siemens-developed agents and those from third parties, supporting system-wide integration and interoperability.

To further accelerate adoption and innovation, Siemens is planning to create an industrial AI agent marketplace hub on the Siemens Xcelerator Marketplace. This marketplace offers access to Siemens and third-party AI agents.

The all-encompassing Siemens Industrial Copilot

The Siemens Industrial Copilot, enhanced by Industrial AI agents, addresses every phase along the industrial value chain, across process and discrete industries:

- Design Copilot: Currently available for NX CAD, the AI assistant helps design engineers manage complex data, evaluate trade-offs, and perform multi-domain tasks. It supports natural language queries to access technical details and simplify design workflows. Siemens is also developing a Hydrogen Configurator to help generate block flow diagrams with defined unit layouts and connections for hydrogen production plants.

- Planning Copilot: Currently in pre-release, this solution uses generative AI to support production planning, resource allocation, and scheduling to improve efficiency and reduce waste.

- Engineering Copilot: Available for TIA Portal, with a managed service planned for 2025, this tool uses generative AI to simplify automation engineering by generating SCL code from natural language input. In process industries, an AI-assisted cloud service for P&ID digitalization has been tested by customers to convert and standardize legacy diagrams.

- Operations Copilot: The Copilot for Insights Hub is offering plant-wide operational insights. Siemens plans to launch an Operations Copilot by late 2025 to assist shop floor workers with machine data queries and error resolution via natural language. For process industries, the Simatic eaSie assistant allows technicians to access equipment data through chat or voice for safer operations.

- Services Copilot: The maintenance copilot Senseye supports diagnostics across the maintenance lifecycle, from reactive to preventive tasks. It has shown a 25% average reduction in reactive maintenance time in pilot projects.

Addressing the skills gap in manufacturing

The Siemens industrial copilot is delivering measurable results in both Siemens’ own plants and customer implementations worldwide. At thyssenkrupp automation engineering, engineers have reported improvements in code quality and development speed. At Siemens’ Bad Neustadt site, the insights hub production copilot turned fragmented data into useful insights.

“In a factory environment, our Industrial AI agents connect different copilots and automate workflows across the entire value chain. This creates a unified approach that makes industrial AI accessible to everyone, regardless of their technical background or experience level,” said Brehm. “We envision a future where Industrial AI agents work seamlessly alongside human workers, handling routine processes independently while enabling humans to focus on innovation, creativity, and complex problem-solving.”

Source: Siemens

About Siemens Digital Industries

Siemens Digital Industries (DI), a division of Siemens AG, is a global leader in industrial automation and digitalization. Headquartered in Nuremberg, Germany, DI offers a comprehensive portfolio of software, automation technologies, and digital services designed to optimize the entire product lifecycle – from design and production to operations and maintenance. Established as part of Siemens’ broader industrial operations over 60 years ago, Siemens DI serves various industries, including automotive, aerospace, pharmaceuticals, energy, and electronics. The company is known for its flagship platforms, like Xcelerator and SIMATIC, which enable businesses to drive innovation, efficiency, and sustainability through digital transformation. Siemens DI employs thousands of professionals worldwide and generates an estimated annual revenue of over €18 billion. Its robust ecosystem supports manufacturers in navigating Industry 4.0, providing tools that combine virtual and real-world data to create innovative, flexible, and scalable industrial systems.

About Siemens AG

Siemens AG, headquartered in Munich, Germany, is a technology powerhouse with a history dating back to 1847. The company operates in sectors including industry, infrastructure, transport, and healthcare, offering products and services that range from industrial automation and digitalization solutions to energy-efficient technologies and medical diagnostics equipment. In fiscal 2024, which ended on September 30, 2024, the Siemens Group generated revenue of €75.9 billion and net income of €9.0 billion. The company employs over 312,000 individuals worldwide, with approximately 90,000 based in Germany. Siemens is recognized as a leading industrial manufacturing entity in Europe and holds a significant position in the global industrial automation and software market.