NUREMBERG, Germany, Mar 7, 2025 – Siemens is introducing the Sinumerik Machine Tool Robot (MTR), a new industrial robotics technology designed to enhance precision and productivity in manufacturing applications. The Sinumerik MTR improves accuracy and productivity across the entire workspace. MTR utilizes an advanced control system that allows industrial robots to function like machine tools. This feature enables precise movements, even when working with hard materials like steel. Such materials require increased cutting forces and more damping. The Sinumerik MTR addresses these demands with a 200 to 300 percent improvement in path accuracy and much greater dynamic rigidity than traditional industrial robots. These advantages make the Sinumerik MTR suitable for sectors such as aerospace, defense, and automotive. It is also effective for high-precision tasks like post-processing 3D-printed metal parts.

The Sinumerik MTR offers added accuracy and a productivity boost, making it well-suited for applications that do not involve process forces, such as waterjet and laser cutting. It operates with Sinumerik One, Siemens‘ CNC system designed for digital integration. With its digital twin capabilities, Sinumerik One enables workflow simulation and testing in a virtual environment, supporting the digital transformation of manufacturing processes. The system is also a component of Siemens Xcelerator, an open digital business platform.

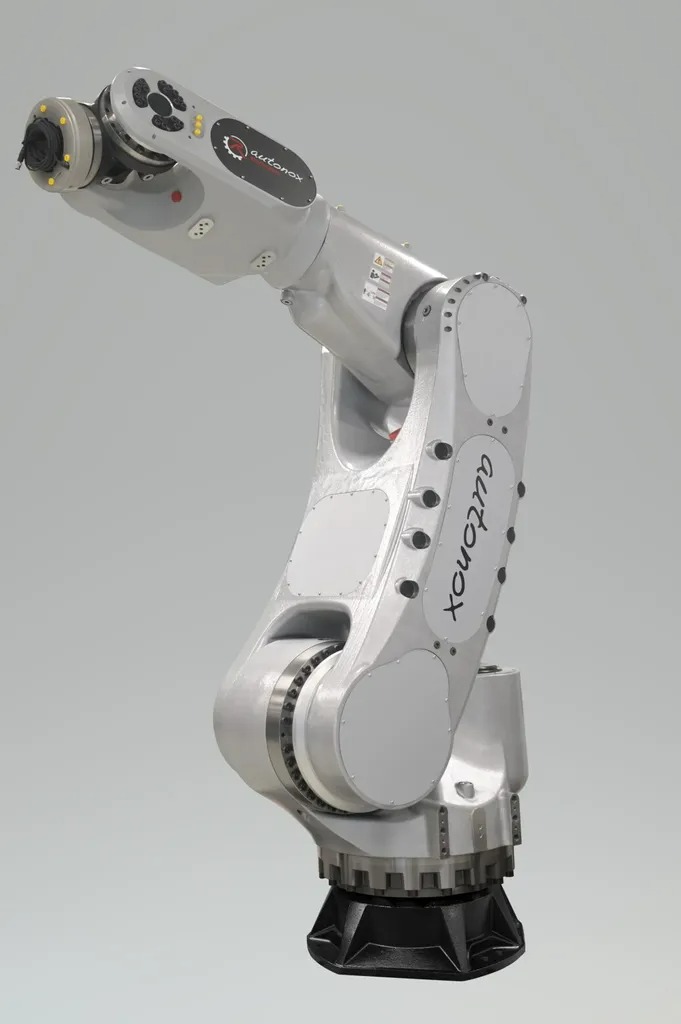

The first partners to integrate the MTR into their robots are autonox and Danobat.

autonox Robotics: A proven partner for innovative solutions

autonox Robotics is a long-standing partner in the Sinumerik Run MyRobot ecosystem. The company is known for reliable robotic solutions that are used in numerous industries worldwide. Autonox provides CNC robotic mechanisms designed to enhance machining precision and efficiency for its customers.

Danobat: A new player in the high-precision CNC robotics market

Danobat is an internationally active consortium and a new Siemens partner. It offers MTR robots ranging from a compact version with a payload capacity up to 220 kg and a 2.6 m reach to the most robust model that can handle a payload up to 520 kg with a 3.6 m reach. The robots combine the accuracy and stability of a machine tool with the agility and flexibility of a 6-axis robot, which creates new manufacturing opportunities for demanding industries like aerospace, e-mobility, and energy. With the integration of the Sinumerik MTR through its partnership with Siemens, Danobat expands its capabilities in high-precision robotic solutions and explores new market opportunities.

Source: Siemens

About Siemens

![]()

Siemens AG, headquartered in Munich, Germany, is a technology powerhouse with a history dating back to 1847. The company operates in sectors including industry, infrastructure, transport, and healthcare, offering products and services that range from industrial automation and digitalization solutions to energy-efficient technologies and medical diagnostics equipment. In fiscal 2024, which ended on September 30, 2024, the Siemens Group generated revenue of €75.9 billion and net income of €9.0 billion. The company employed around 312,000 people worldwide on the basis of continuing operations. Siemens is recognized as a leading industrial manufacturing entity in Europe and holds a significant position in the global industrial automation and software market.

About autonox Robotics

Established in 2002, autonox Robotics GmbH specializes in developing and producing controller-independent robot mechanics, offering a range of robot structures, degrees of freedom, payloads, and working ranges. The company serves industries including packaging, food, pharmaceutical, automotive, and machine tools. Headquartered in Willstätt, Germany, autonox Robotics operates a 4,500 m² production facility and a 1,600 m² administration area, employing approximately 70 staff members. Additionally, the company has a branch in Suwanee, GA, to support customers in North America. autonox Robotics is recognized for providing unique mechanical solutions that add value to robot projects worldwide.

Siemens Digital Industries

Siemens Digital Industries Software provides comprehensive solutions for digital transformation, offering software and services that enable companies to improve product design, manufacturing, and operational processes. It serves a wide range of industries including automotive, aerospace, industrial machinery, electronics, and consumer products. Siemens Digital Industries Software has contributed towards innovation in manufacturing and product lifecycle management (PLM). The company is headquartered in Plano, TX, and is part of Siemens AG. Siemens Digital Industries has a workforce of around 70,000 people worldwide.

About Danobat

![]()

Established in 1954, Danobat is a Spanish cooperative specializing in the design and manufacture of advanced machine tools, including grinding machines, lathes, milling and boring machines, and precision robotic systems. The company serves industries such as aerospace, automotive, energy, and railways and plays a key player in the machine tool sector. Headquartered in Elgoibar, Gipuzkoa, Spain, Danobat operates globally with production plants and service centers across Spain, Germany, the Netherlands, Italy, the UK, and the USA, supported by sales and service team spanning 40 countries. As of 2019, Danobat employed approximately 1,300 individuals and reported revenues of €267 million. The company is part of the Mondragon Corp., a cooperative consortium, dedicating between 8% and 10% of its income to research and development. This commitment underscores Danobat’s dedication to delivering high-precision, technologically advanced solutions to its diverse clientele.