NUREMBERG, Germany, June 25, 2025 – At automatica, the trade show on automation and robotics, Siemens announced plans to extend its Operations Copilot to driverless transport systems and mobile robots. The Operations Copilot is designed as an industrial interface for machine operation and maintenance. As autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) operate as AI-driven physical agents, the Copilot will function as a control interface for humans. It allows users to configure tasks such as material handling and goods transport within factory environments. This development contributes to advancing automation workflows by incorporating generative AI into factories.

Operations Copilot will be enhanced with agents for AMRs and AGVs

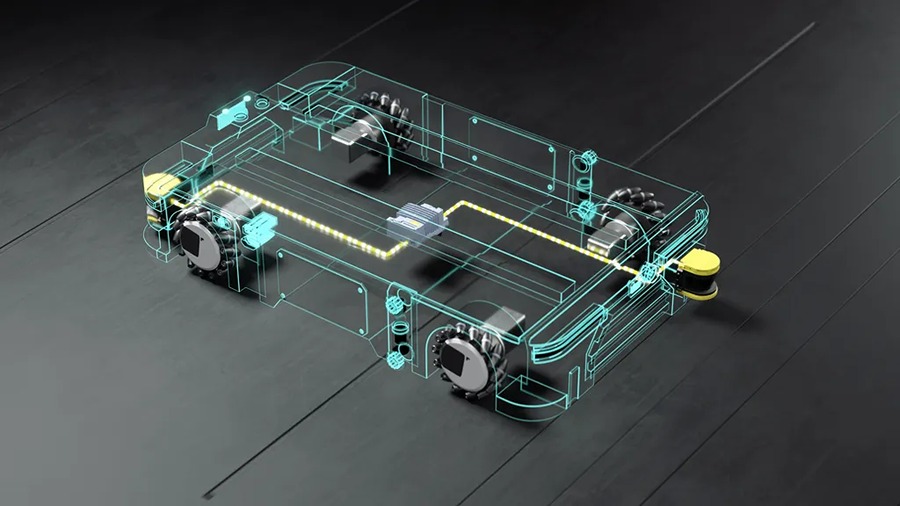

Siemens plans to extend the Operations Copilot by introducing AI agents for AMRs and AGVs. The agents will assist with both the commissioning and operational management of vehicles and fleets. Commissioning is a complex process that involves integrating AGVs into the factory’s IT and OT systems and configuring them for specific conditions like routes and transfer stations. The Operations Copilot supports this process by using data from AGV sensors and cameras to create a representation of the operating environment. It also provides access to technical documentation and retrieve system data through its agent interface. This helps commissioning engineers and operators’ complete setup tasks, troubleshoot issues, and accelerate deployment.

“By integrating both physical and virtual AI agents into our Operations Copilot, we’re unlocking a new dimension of interaction between humans, robotics, and AI,” said Rainer Brehm, CEO of factory automation at Siemens. “This enables our customers to deploy autonomous transport systems more quickly, operate them efficiently, and enhance safety – bringing us one step closer to a fully autonomous factory.”

New Safe Velocity software enhances safety on the shop floor

AGVs use navigation and sensor technologies to operate autonomously in production and intralogistics environments, adjusting their movement when objects or people are detected. They slow down, stop, or reroute as needed. Siemens’ Safe Velocity software enables fail-safe monitoring, permitting the protective fields of safety laser scanners to fine-tune in real time. TÜV-certified, the software is compatible with hardware and software from various AGV manufacturers and meets industrial safety compliances. Safe Velocity reduces the need for additional safety hardware, simplify system architecture, saving space, minimizing cabling, and reducing engineering effort, and maintain functional safety.

In the future, the Operations Copilot will interact with AI agents like Safe Velocity to analyze data from safety laser scanners and monitor the speed of AGVs. The Safe Velocity agent supervises autonomous vehicles and can cooperate with other agents designed for AGV and AMR applications. Siemens is creating a multi-agent system where the Operations Copilot manages both physical and virtual AI agents. This setup helps connect real-world processes with digital tasks, allowing both to work together.

Siemens is showcasing how AI and robotics are transforming automation – and offer a glimpse into future developments – at automatica in Munich from June 24 to 27, 2025.

Source: Siemens

About Siemens Digital Industries (DI)

Siemens Digital Industries (DI), a division of Siemens AG, focuses on industrial automation and digitalization. Based in Nuremberg, Germany, the division provides software, automation systems, and digital services that support the full product and production lifecycle—from design and engineering to manufacturing and maintenance. With a history extending over six decades, Siemens DI serves key sectors including automotive, aerospace, pharmaceuticals, energy, and electronics. Its technologies, such as the Xcelerator platform and SIMATIC automation systems, are designed to integrate physical and digital processes, enabling data-driven manufacturing and operational efficiency. The division reports annual revenues exceeding €18 billion and employs approximately 70,000 people globally. Its portfolio supports manufacturers in implementing Industry 4.0 strategies by linking simulation, automation, and real-time data in scalable systems.

About Siemens AG

Siemens AG, headquartered in Munich, Germany, is a global technology company operating in sectors such as industry, infrastructure, transportation, and healthcare. Established in 1847, Siemens offers a wide range of products and services including industrial automation systems, digitalization solutions, energy-efficient technologies, and medical diagnostic equipment. In fiscal year 2024, ending September 30, Siemens reported revenues of €75.9 billion and a net income of €9.0 billion. The company employs over 312,000 people worldwide, with approximately 90,000 based in Germany. Siemens is among Europe’s largest industrial manufacturers and plays a significant role in the global markets for automation and industrial software. The company also holds a majority stake in Siemens Healthineers, a prominent medical technology provider. Siemens leverages advanced technologies such as industrial and generative AI to enhance efficiency and sustainability across its customer base.

About automatica

automatica is an international trade fair on smart automation and robotics, organized by Messe München GmbH and held every two years in Munich, Germany, since 2004. The event covers a range of technologies, including industrial robotics, service robotics, machine vision, sensor systems, assembly and handling solutions, and AI-based automation. It serves industries such as manufacturing, automotive, electronics, logistics, and healthcare, providing a platform for companies to present and evaluate advancements in automation and digital production. automatica facilitates technical exchange between manufacturers, technology providers, and users, focusing on solutions that improve production efficiency and system integration.