Product CAD data is among the most valuable assets a company can possess. It forms the foundation of the product development lifecycle, acting as the on-ramp to a much broader process. Since most of the work in developing a product occurs after the creation of the initial CAD files, it becomes critical to manage not only the CAD data itself but also all related product information effectively.

Product CAD data is among the most valuable assets a company can possess. It forms the foundation of the product development lifecycle, acting as the on-ramp to a much broader process. Since most of the work in developing a product occurs after the creation of the initial CAD files, it becomes critical to manage not only the CAD data itself but also all related product information effectively.

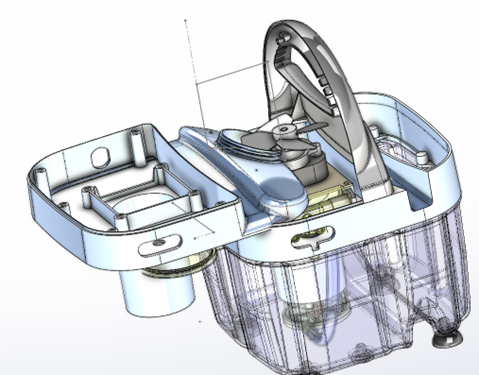

SolidWorks was initially designed to integrate seamlessly with third-party applications for various purposes, including photorealistic rendering, stress analysis, and product data management (PDM), among others. Although the platform offers built-in options, many companies choose alternatives based on factors such as cost, usability, and functionality. The CAD data produced in SolidWorks is just one part of the overall gamut of product information.

What Data Goes into Your Design?

The data that defines a product doesn’t come solely from engineering. Input often comes from departments like purchasing, manufacturing, assembly, quality assurance, testing, and service. All these departments contribute crucial information that should be associated with the original design files to ensure a comprehensive understanding of the product.

While CAD geometry is valuable, it cannot convey everything. For example, geometry alone won’t tell you what material is being used, the process by which the part will be created, who is manufacturing it, or where else the part is used. It won’t clarify when the documentation was released to manufacturing or what kind of test fixtures will be necessary once the product is assembled. These are all critical aspects of metadata—contextual information that must be connected to the physical design.

How Do You Manage All this Data?

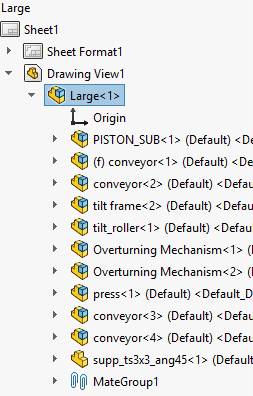

Many companies begin by storing CAD files in standard Windows folders. This approach often includes informal document release practices and inconsistent naming conventions. While initially manageable, such a system quickly becomes unstable. SolidWorks documents, in particular, require a careful and nuanced approach. Assemblies and external references can easily break if files are moved or renamed improperly. Managing these references within a manual file system involves adhering to complex rules that most users don’t fully understand or follow consistently.

As complexity grows, so do the problems. It’s all too easy to overwrite important files or break links between documents. Searching through folder trees is slow and inefficient, and there is no straightforward way to generate a comprehensive bills of material (BOMs), especially one that includes both standard off-the-shelf components and non-physical parts like firmware, paint specifications, or lubrication materials.

To make matters worse, SolidWorks doesn’t simply look in one location for its references—it checks multiple locations before it searches the last known save location. This kind of opaque behavior makes manual management increasingly unworkable as your product matures.

What If You Need to Assign Permissions?

Access to this data is also a major consideration. Design data and associated metadata are only valuable if the right people can access them—and dangerous if the wrong people can. You wouldn’t want a sales rep quoting specifications from an outdated design, or a vendor accessing unreleased prototypes. Yet in a manual system, maintaining proper access control becomes an ongoing challenge that often falls on already overextended IT staff. If your file structure is constantly evolving, the task of updating permissions and managing who sees what becomes unsustainable. Over time, manual file management becomes a liability rather than a solution.

Access to this data is also a major consideration. Design data and associated metadata are only valuable if the right people can access them—and dangerous if the wrong people can. You wouldn’t want a sales rep quoting specifications from an outdated design, or a vendor accessing unreleased prototypes. Yet in a manual system, maintaining proper access control becomes an ongoing challenge that often falls on already overextended IT staff. If your file structure is constantly evolving, the task of updating permissions and managing who sees what becomes unsustainable. Over time, manual file management becomes a liability rather than a solution.

Change is Inevitable

Then there’s the question of change. One of the earliest lessons learned in engineering is that design is never truly finished. Initial releases are revised, sometimes multiple times, as feedback is gathered and real-world constraints emerge. Change is not an exception—it’s a rule.

Each company handles change in its way, but manual methods, such as routing stacks of paper prints across departments, are slow, risky, and prone to human error. The true danger in these systems isn’t the technology, but rather the reliance on people’s memory to follow procedures consistently. Even when those procedures are clearly defined, the burden they place on users often leads to workarounds, mistakes or simple forgetfulness.

Manual systems, ironically, require the most expertise to manage, yet they are often used by teams that are least equipped to handle them effectively. This disconnect is what ultimately drives the need for a better solution.

Manual systems, ironically, require the most expertise to manage, yet they are often used by teams that are least equipped to handle them effectively. This disconnect is what ultimately drives the need for a better solution.

The Answer is Automation

The answer lies in automated PDM systems. These platforms embed best practices directly into their architecture while allowing for the flexibility required by different organizational workflows. You might even extend the discussion from the initial product design data to include change data and the entire product lifecycle of the product, which you might refer to as PDLM – Product Data Lifecycle Management.

Conceptually, PDLM systems utilize a relational database to store information associated with part numbers, assemblies, and product configurations. This database also manages shared components, such as hardware or consumables, and tracks the usage of every part and subassembly. The CAD files themselves are stored securely in a location called the Vault, which may reside on a company’s internal servers or in the cloud. For instance, tools like Sibe.io offer cloud-based vaulting solutions.

When you retrieve a SolidWorks assembly from the Vault, PDM maintains database records of all the latest revisions of all referenced documents and sends copies of these files to the user’s local working directory. You don’t have to worry about how SolidWorks finds externally referenced files, how it handles revisions or any of the complex data management rules. The system takes care of this for you.

Throughout this process, the system preserves the integrity of file references, including in-context relationships and external links. This removes a major pain point for SolidWorks users, who would otherwise have to take great care to maintain file references manually. With PDM, the system automatically enforces the rules for reference management.

To illustrate this in practice, imagine an engineer creating a subassembly as part of a larger product. The subassembly comprises several parts, each represented by both 3D models and 2D drawings. The manufacturing team uses the 3D models to generate CNC tool paths, while quality assurance refers to the 2D drawings to confirm dimensional accuracy. The assembly team may have yet another document guiding the proper build and testing of the product. In a PDM system, all these documents reside in the Vault and are connected through links in the database, ensuring consistency and traceability.

Change Workflow and Routing

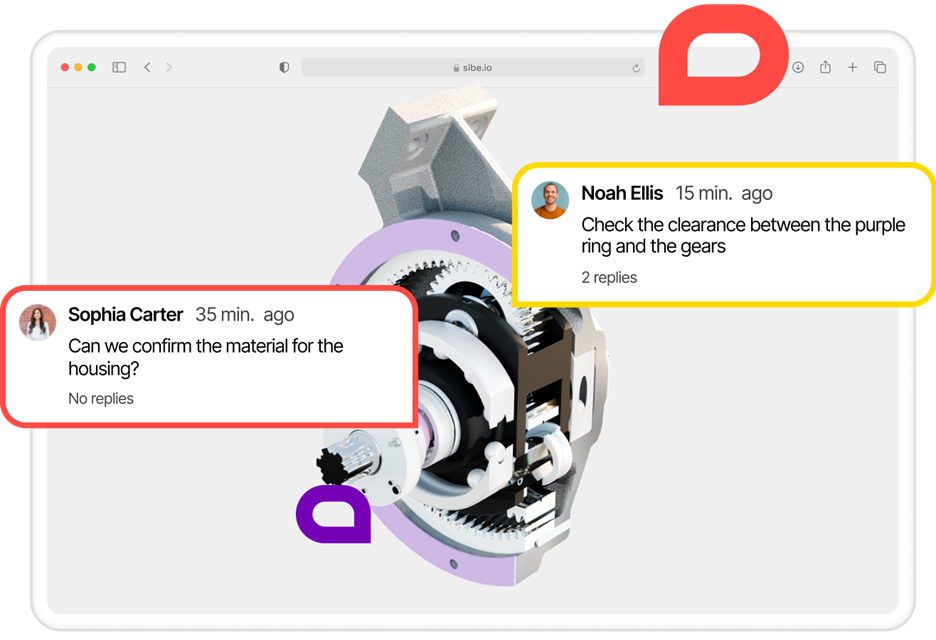

One of the bigger advantages of a full-blown PDLM system is that it can electronically manage your entire change process. To do this, a visual flow chart is established to represent the flow of data through your company to approve changes. This includes electronic markups, signoffs and flow routing. This type of automation is incredibly liberating for all the departments that must route documents through.

Anyone who can initiate a change has access to viewers for all types of data in the Vault. The viewer includes markup capabilities to allow non-specialists to convey the nature of the required change. The change document itself will enable links to all affected documents. Comments included in the markup capability provide collaboration opportunities to work together on changes. If you are using a Cloud-based system such as Sibe.io, this type of commenting system suddenly becomes multi-site or even global collaboration.

PDM Controls Permissions and Access

PDM Controls Permissions and Access

Access rights are managed at a granular level. Engineering may have full access to design files but only read access to manufacturing documents. Manufacturing teams can read and write CNC data, while QA may be restricted to viewing only. The system tracks who can view and modify what, ensuring that data remains both secure and accessible.

Revisions are also controlled within the system. Each part number in the database includes a description, revision level, status (such as pre-release, released, or obsolete), and other metadata. Users can search across all this data to find exactly what they need. Furthermore, roles and permissions can be customized, allowing users to view, print, edit, create or delete files as appropriate. A single user may hold multiple roles depending on their responsibilities.

Every PDM implementation needs a capable administrator. This responsibility is typically shared between the IT department and the design or engineering departments. This role requires deep knowledge of both database management and product development processes. Admins must also be familiar with the various data formats generated throughout the lifecycle, including CAD models, simulation data, spreadsheets, word processing files, images, and more.

Conclusion

CAD data gains actual value only when it is appropriately managed, shared, and controlled. While manual systems may suffice for a time, they quickly fall apart under the pressure of growing complexity and change. A modern, automated PDLM system transforms CAD files from static models into the central, trusted source of truth for your entire organization, turning design data into an accessible strategic asset that minimizes mistakes, fuels innovation, enables collaboration, and operational efficiency.