The typical homeowner needs a truck occasionally, such as when they move from one home to another. Businesses and government agencies require trucks more frequently and for a variety of reasons. For example, my hometown of Novato, California (population 50,000), needed to cut down trees that were over a hundred years old. Needless to say, Novato does not keep cherry pickers that can reach over 30 feet. They had to find them. However, even larger governments and agencies, including state departments of transportation, will need trucks outfitted for specific tasks and not have trucks in their existing fleet.

These days, filling a need, no matter how specific, is as simple as an Internet search. For example, “custom truck for (your need) near me,” which is bound to Custom Truck One Source near the top.

Custom Truck One Source exists for a singular purpose: to create trucks for your specific purpose. If the company has not already created a truck to meet your needs, it will make one. Or rent it from one of 40 locations in the U.S. and Canada.

From Humble Beginnings

Custom Truck One Source’s headquarters are in Kansas City, Missouri, where it maintains a sprawling (over 75-acre) manufacturing facility. It all started in 1996 when Fred Ross opened a family business and called it Custom Truck Sales. Its first trucks had salvaged equipment bolted onto used truck bodies. Ross was betting on satisfying niche needs too small for big truck companies, all of whom seemed content in building trucks only for hauling goods. The company set about fitting used trucks with cranes, lifts, plows… They soon discovered enough niches to prosper. The company has sold a majority of itself to private equity firms and gone public, moves that have provided capital to acquire related businesses and grow significantly. They not only make and sell trucks, but they also maintain an active online marketplace for the vehicles, supply parts, and will even buy back your truck when you’re done with it. The company currently reports $1.8 billion in revenue and has over 2600 employees.

As Custom Truck grew from humble beginnings, so did their trucks — and their vision. The company lists trucks for a variety of specialized needs on its website. Their trucks are masterpieces of customization.

Mass Customization

Custom truck manufacturing is not for the timid, and prospective custom truck customers may be wise to leave it in the hands of professionals. Kyle Gerber, VP of Engineering and Chris Beougher, Engineering Systems Manager, are two such professionals. They manage the engineering efforts and CAD systems, respectively, at Custom Truck One Source. The company had previously used AutoCAD, then transitioned to SolidWorks and is now transitioning to Onshape. They are eager to tell their story on an Onshape webcast.

Any transition from one CAD system to another is not easy, especially if the CAD program is deeply entrenched in the company and the industry, as is SolidWorks. The resistance to change is not because engineers fear that another CAD program will not be as capable. Over the years, Onshape has acquired most of SolidWorks’ capabilities, rendering a feature-to-feature comparison between the programs largely moot. Instead, a transition faces challenges other than technical ones.

“The more difficult portion of the transition was actually on the personnel side,” says Kyle. “Engineers love their CAD systems. They’re just so tied to them. It’s part of who they are. They will fight to keep their CAD program.”

The pair debunk any notion of being against SolidWorks. Still, when they considered the advantages that Onshape offered their engineers, they felt that a transition, no matter how painful, had to occur.

“We are not SolidWorks haters,” Kyle is quick to say. “We have thousands of hours of experience in SolidWorks. I recommended SolidWorks to the company and have used it almost my entire career.”

The transition from Onshape to SolidWorks was instigated when SolidWorks itself was undergoing a transition, says Kyle.

“They are pushing users towards the 3DEXPERIENCE,” says Kyle. “But from our evaluation and from hearing from others in the industry, 3DEXPERIENCE is not ready.”

SolidWorks’ emphasis on 3DEXPERIENCE and price increases for the desktop version had made Kyle’s eyes wander. The engineers were, for the most part, satisfied with SolidWorks, but problems were emerging between the design software and the PDM.

“As far as performance goes, we were experiencing some very slow performance from SolidWorks in the PDM vault. Our engineering department was grinding it to a halt with some of the larger assemblies.”

“At the end of the day, it was less about CAD than it was about data management,” says Kyle.

On To Onshape

Custom Truck One Source is in the process of transitioning to Onshape from SolidWorks. The company maintains both CAD systems during this transition.

Kyle and Chris say that, on the whole, engineers have gone from citing what Onshape lacks to Onshape’s advantages over SolidWorks. They echo Onshape’s marketing: a single source of truth, being cloud-based, and the built-in collaboration… but, again, it is the built-in seamless PDM, plus the access Onshape provides to everyone to the latest model and configurations, that has the pair singing Onshape’s praises. Onshape’s use of the cloud offers users an infinite amount of computing power, letting Custom Truck’s engineers customize at will. Engineers can design and create a wide range of truck configurations. Salespeople can show different configurations on iPads at customer sites or online. And the model shop, machine shop and assembly workers can all be sure they are working off the latest design.

Custom Truck One Source has gone from being bogged down in configurations, with PDM the bottleneck, to where PDM is invisible. Configurations are accessible in the blink of an eye.

Configurations can be created in Onshape in a manner similar to SolidWorks with the DriveWorks add-on. DriveWorks may be the most robust configurator known to CAD, but it is an expensive add-on to an already expensive CAD program. Chris knows all about DriveWorks, having used it in previous companies. He shows Onshape being used similarly to DriveWorks, with configurations created by making choices in a dropdown menu.

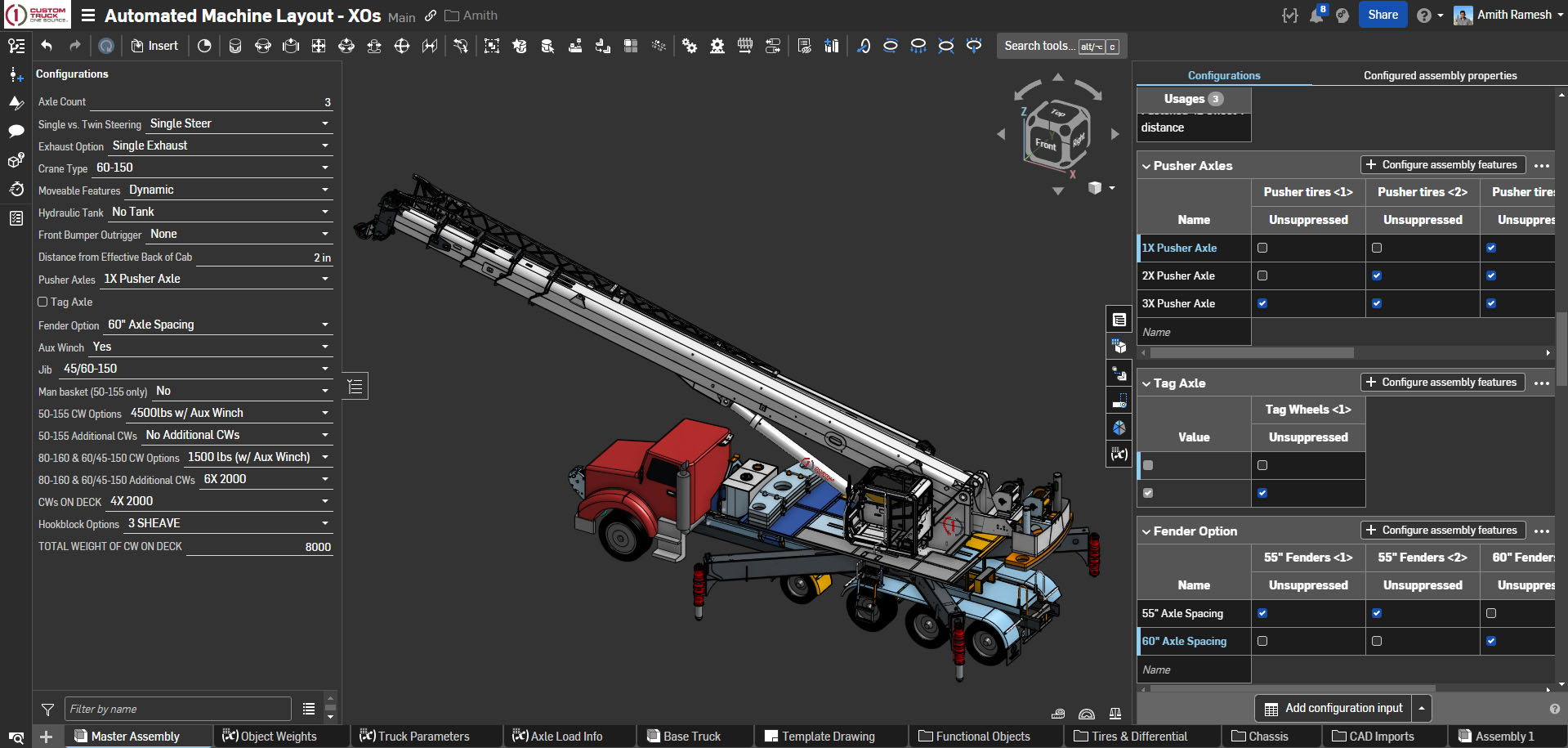

Chris dives into Onshape to show us how. He can select a base model truck chassis and vary the wheelbase, number of axles, and space between them, as well as choose single or dual exhaust, and more. He can suppress or unsuppress objects. The Onshape model is displayed on the right in the main window (figure above) and updates in real-time as selections are made.

“We used to have to create configurations in Excel,” says Chris. “It would calculate centers of gravity and crunch all the numbers. Trying to do that in SolidWorks might have taken 45 minutes. It was just so computationally intensive on our PCs that we simply didn’t do it. It’s pretty exciting, being able to do that in a CAD system.”

Custom Truck One Source, being a power user, provides a solid endorsement for Onshape. The key takeaway is that it has transitioned from being just a good deal, being able to do most of what SolidWorks could do, to becoming a CAD program that can do more. Nowhere is this more apparent than when the webinar shows the effortless handling of multiple configurations. That may be the lifeblood of custom manufacturers, such as Custom Truck One Source, but it speaks to the infinite computing power available to all Onshape customers. Powerful CAD is no longer limited to those with $5,000 workstations — or limited by those same workstations. Instead, powerful CAD can be had on any device and serve every user.